Content:

Owners of private houses have known for a long time that raising broiler chickens on their own at home is a very profitable occupation, the owner will always have at his disposal organic meat. For these purposes, it will be useful to know how a cage for broiler chickens is made with your own hands.

general information

Before you start manufacturing, you should familiarize yourself with the minimum requirements for bird cages. Otherwise, there will be no benefit from such savings.

Some owners suggest making so-called battery cells. Their main advantage is that they save precious space, but at the same time they have all the necessary amenities for birds: a drinker, a feeder and a habitat. One of the biggest mistakes novice poultry farmers can make is making oversized cages, which will only cause inconvenience. Heating in these "boxes" will suffer, which is very bad, since broilers like comfortable and warm conditions, especially as chicks. Heating is an important part of broiler cages.

When making mini broiler pens, it is recommended to use proven and sturdy materials, carefully following the drawings. Before you start tinkering with houses, you need to properly think over the scheme, calculate the sizes, using mathematical calculations. It is worth avoiding flaws and even small omissions, like an unfinished nail, due to which the birds will be injured.

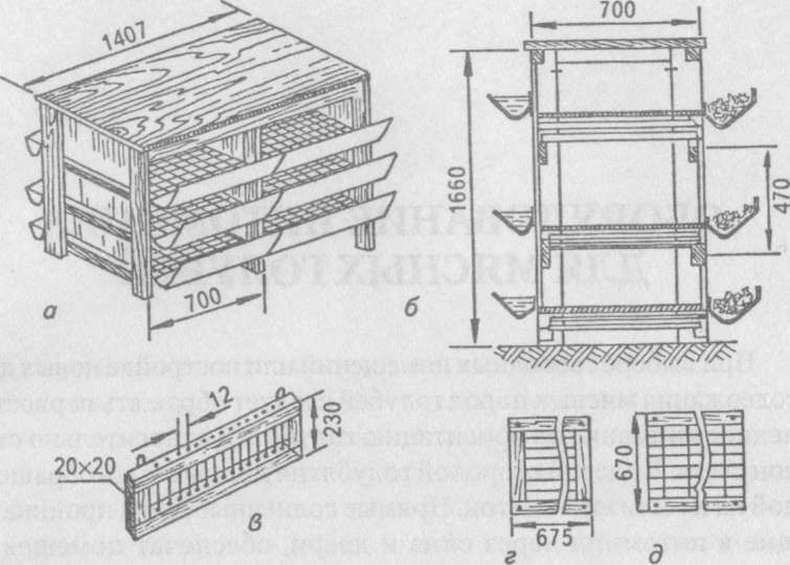

Description, dimensions, drawings

Before you build your own broiler cages, you should decide how many birds the owner will deal with. On average, mini-houses are made, counting on the following figures:

- for 10 heads;

- for 20 heads;

- for 50 heads.

When making cages for broilers, you should expect that they will not be individual, but for a couple or even more chickens. These massive birds are rapidly gaining weight and begin to take up a lot of space. In addition, if the constructed structure is fragile, they can easily render it unusable. In order to avoid such embarrassment, it is worth strengthening the structures with reinforced materials.

To start making home cages, it is recommended to stock up on the following materials:

- metal mesh, not too thick, which will allow sunlight and air to pass through, to maintain a comfortable atmosphere for birds;

- plywood sheets that will serve as walls;

- metal sheets - auxiliary materials for access to food and drink for birds;

- screws, nails, self-tapping screws, with the help of which all other parts will be fastened together;

- various equipment designed to heat the home.

All these details are freely available in shopping malls, it will not be difficult to acquire them.It is recommended to purchase a slightly larger amount than expected, so that in case of miscalculations or loss of material, do not interrupt the business and do not run for a replacement. If an entrepreneur decides to profit from breeding chickens, it is worth making more than 10 cages, taking into account that each will accommodate about 3 broilers on average.

Making cells

To make drawings, you need to determine the number of chickens that will live in them, how many tiers are supposed. The main thing is that they are compact, while easily accommodating several birds at once. This is followed by a scheme for 10 goals, which can be converted to 20 or 50.

Several stages are assumed:

- You need to make 6 racks, the length of which should be 165 cm, and the height and wide side should be 7 * 2 cm.

- The manufactured racks must be combined into a single frame. The dimensions are as follows: 2 racks - 5 * 2 cm, 6 racks - 3 * 2 cm, 3 racks - 10 * 2 cm.

- Further, 9 side-type walls are made of plywood. Their dimensions are 31 * 58 cm.

- A compartment is also needed where bird waste will be collected. For this, pallets are made from metal sheets. Length 31 cm, height 21 cm and width 68 cm.

- The upper part - the roof - can be made of plywood. Dimensions 70 * 140 cm.

To be able to roll the cages from place to place, for example, when cleaning, you can screw the wheels to the pallets. In addition, if it is not possible to make pallets, then you can attach trays purchased in the store. Brackets are needed to attach the feeders and drinkers.

If a poultry farmer wants to raise healthy birds, there are some breeding guidelines that need to be followed. For example, newborn chickens, which are only a day old, can be placed 10 pieces. in one cell, the dimensions of which are half a square meter. It is not recommended to replant chickens before finishing feeding. At the same time, it is very important to observe the temperature regime of 31-35 ° С. As broilers grow older, the degree can be lowered by 2 months. For older chickens, 17 ° C is suitable.

Chickens also need a certain light regime. Until the chicks are 3 weeks old, cage lighting is required around the clock. After they step over the 21 day mark, you can gradually lower the hour mode to 17 hours.

Broiler net

When making cages for broilers, craftsmen use several types of nets, which can be easily purchased at hardware stores. Among them:

- welded mesh;

- Rabitz;

- CPVS.

They are all commonly used by broiler cage builders. But the majority prefer the netting mesh.

Rabitz

Pens for broilers are made from the netting. She sought the greatest popularity from summer residents, who make fences, supports for climbing plants and use it in construction.

Pros of the mesh netting:

- low cost;

- ease of use and manufacture.

It can be difficult for birds to immediately get used to the mesh floor, so before releasing them immediately, it is better to underlay something solid for the first week. They will gradually get used to it, it will not be so difficult for the bird to move on the net after the hard surface is removed.

CPVS mesh

Not so popular with summer residents, but also applicable in everyday life, an all-metal expanded metal mesh is used in most cases when working with plaster. But, if the barbs with which the mesh is equipped are very convenient for the molar, they are dangerous for the chicks.Therefore, before laying such material under the chickens, you should get rid of the serifs with a file or sandpaper.

Welded mesh

After the netting, the most popular is the welded netting, which is also convenient for building cages for broiler chickens. Pieces of steel wire are spot welded in perpendicular directions. This type of mesh is valued for its hardness and strength, high manufacturability. At the same time, which is quite surprising, it is very inexpensive.

Tips & Tricks

Experienced poultry farmers know that there are many nuances that beginners may not know. Therefore, before you start making cage houses for home or outdoors, it is recommended that you familiarize yourself with some tips that will greatly facilitate the course of business:

- When making a floor, you should give preference to concrete or clay concrete with screeds. But, before starting to fill it, it is advised to fill the space of the future house with sawdust or unnecessary wood shavings.

- If the broiler cage is being made in an area with cold temperatures, it is recommended that the walls are properly insulated. The thickness should not be less than 15 cm.

- It is very important for birds that small midges are not found in their habitats, so it is equally important to install mosquito nets there. Otherwise, the midges, attracted by the fresh smell of the products of the chicken's vital activity, can enter the nostrils of the birds, which will lead to death.

- When making a chicken coop, it is very important to provide for the possibility of fresh air. For example, make a window, and the bird will always be fresh. It is very important to remember that window openings should not be less than 1/12 of the area of the entire cage space.

- For even better air access, it is recommended to make holes (ventilation) in the walls slightly closer to the floor and on the ceiling. But it is worth remembering that in winter they need to be covered, otherwise the cold air will kill the birds.

- In order to create a more natural bird habitat, it is recommended that the birds be able to sense and see yellow light, which can be achieved by using incandescent bulbs.

- A water barrier designed to keep water out of birds and damage to equipment and all materials will also be useful for insulation.

Thus, raising broilers at home is a profitable business that pays off over time. The biggest plus, which cannot be argued in any way, is that pure, organic meat grown at home cannot be compared with purchased one. At the same time, making cages for broilers is not a difficult and hopelessly impossible undertaking. One has only to stock up on certain materials that are freely available and start manufacturing according to previously prepared schemes. Armed with bars, batteries and other tools, you can get to work. If original ideas suddenly appear, you can immediately put them into action so that the cells turn out not only convenient, but also creative.