Content:

Injuries inflicted on the hooves of cattle not only cause suffering to animals, require additional treatment costs, but also reduce their performance characteristics. In order to prevent this type of injury, it is recommended that cows regularly trim their hooves. To perform this work in a more convenient way, there is a machine for processing cattle hooves.

Care and breeding rules

When breeding cattle (cattle), you need to try very hard to raise a cow from a calf. Therefore, livestock breeders are trying to find and apply various ways to reduce costs and improve the efficiency of their activities. Unfortunately, in the pursuit of best practices, the basic rules for caring for animals are forgotten.

One of the most important issues is to ensure the health of the hooves. Over time, they can be damaged, overgrown with a keratinized, dead layer. If not helped, it can reduce the performance of the animals. For example, scientists have calculated that in such cases, for various breeds, milk yield decreases by an average of 14%, and fertility rates - by 16%. In addition, there is an increase in the cost of treating a sick animal.

Cattle hoof processing

Over time, the hooves become overgrown with a keratinized and dead layer, which is prone to cracks and can cause damage.

To process, peel off the stratum corneum before the live part of the hooves appears, it must be cleaned so as not to damage it. It is better to cut it off here than to damage this part of the hooves. This can cause animal fear.

Hoof machines

In practice, we are talking about special frames and mounts that can accommodate one cow. They are usually located at the exit from the barn. When the cow enters, the back door is closed. In expensive designs, special belts may be provided in the configuration with which you can lift the cow up to the desired height. The head is fixed, limiting it from the sides.

Split for cattle

A split is an important part of the machine, where the head of the animal is fixed. A split for cattle is usually made in the form of two flaps, which press the cow's head from the sides. To make a split for cattle with your own hands, you can make it in the form of two flaps.

Cattle fixation machine

It is a large wooden or metal frame. You can order and buy them, or you can make them in a simpler form yourself. Typically, the dimensions of the workover machine are up to three meters in length, about two meters in height and up to one and a half meters in width. In the front part of the cattle hoof trimmer there is a frame in which the head is fixed (split). A gate is placed at the back, which prevents the cow from going back or another cow trying to enter the frame.

Hoof disc

It is used to clean the stratum corneum from the hooves. There are two main options:

- Disc designed for grinding.

- Using special knives.

In the latter case, there is space on the disk for attaching removable knives. There are usually three or six of them.

Usually, disks with knives are used for rough initial cleaning. Grinding wheels are used for final, finer processing. In this case, care must be taken not to touch the meat layer.

The discs are made in such a way that they can be used with standard sanders.

Do-it-yourself anti-break for cows

This device is designed to restrict the movement of the cow during milking. There are one-way and two-way anti-break options.

The first one is considered classic. Such an anti-break for cows looks like this.

The bottom is hooked onto the crease that runs from the cow's hind leg forward. The upper part extends behind the spine. The button, which looks through one of the holes, is located on the spring bar, which pushes it outward into the holes, fixing the total length of the device. If you press the button, you can change the length of the anti-break. If it is too loose for the animal, it will be ineffective. You need to adjust the length so that it fits tight.

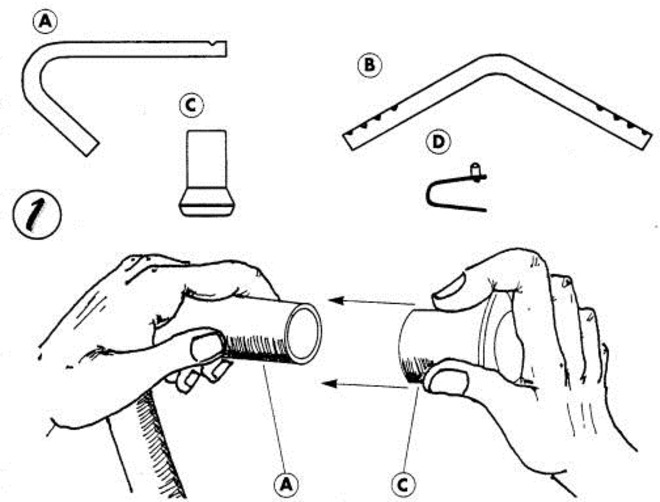

To make an antibryk for cows with your own hands, you need to make the following details, according to the diagram.

You will need two bent pieces of pipe A with one hole each, which will need to be inserted into the symmetrical bent pipe B that has a larger diameter. First, you will need to insert into them along the corner spring D, so that the button goes into the hole. When inserting the tubes, the buttons must be pressed with the palm of your hand. Rubber caps must be put on the outer ends of the pipes to protect the cow from scratching. Here's how to make your own anti-kick for cows using metal parts.

Do-it-yourself split for cattle

The machine for fixing cows can be made independently. The easiest to manufacture is a wooden structure.

For manufacturing, you can take a wooden beam 100 x 100 mm. To do this, you need to dig six pillars in a rectangle into the ground. The width should be from one to one and a half meters. The length is 2.5-3 meters. The height of the front two beams and the middle ones above the ground should be 1.5-2 meters. The hind ones should be lower. A crossbar is placed on them, to which the leg will be tied, on which the hoof will be processed. It must be able to support this weight. The remaining two beams are the same length as the front ones and are about 40 cm in front of the rear ones.

A feeder with hay is installed in front. It is provided in the drawing so that during the procedure the cow can eat and feel more comfortable and calm.

The hind leg is tied with a belt to the horizontal bar from below and the necessary operations are carried out. Along the sides, they are nailed on a horizontal board located at the same height as the back. When processing the front hoof to the board, fix the desired leg from below with a belt.

Tips from experienced breeders

A few tips:

- Although it is relatively easy to make a machine made of wood, it nevertheless will not have the durability that metal has.

- It is advisable to install the machine at the exit from the barn. In this case, you do not have to make special efforts to bring the animal there.

- Trimming the hoof should be done until a white color appears, which means that the stratum corneum is completely cut off.

- If in the process of work the hoof was injured, it is necessary to cauterize it with iodine.

The use of a special machine for fixing the animal when processing hooves will significantly facilitate the implementation of this processing.

Do you have a diagram, drawings, for making a clamp or fixing a cattle head?