Content:

Pig breeding is profitable if the workflow is organized correctly. One of the important stages is providing animals with food. It is not only the quality of the food that matters, but also the competent choice of the feeder. With its help, you can reduce food costs and increase the profitability of the farm.

What is a feeder for?

A pig feeder is a container of a certain size into which the farmer places food. The design must meet certain requirements in order to:

- the animals had unhindered access to food;

- did not throw food around the room;

- food remained clean and did not cause poisoning.

Feeders are selected based on the age of the animals, their number and gender.

Types and requirements for feeders

There are different types of pig feeders. The expediency of their use depends on the number of livestock and the financial situation of the farmer.

The given classification is conditional. It is possible to intersect and combine several varieties in one design.

By type of feeder there are:

- stationary - fixed in one place. The animal cannot move the container around the room;

- mobile - they can be moved around the pigsty. There are one-sided and two-sided. In the latter case, there is a longitudinal partition;

- individual - designed for one pig;

- group - provide food for all livestock.

By design:

- standard - this category includes a trough for pigs, a basin and other similar feeders;

- automatic - also called bunker. Designed for loading large amounts of feed (for 2-3 days). Food enters the tray as needed. Such designs greatly simplify the care of large livestock. They are used for fattening, feeding of pregnant gilts, piglets rearing.

General sanitary requirements:

- troughs must be kept clean. They should be easy to wash and clean;

- they must not be allowed to enter garbage and pig feces;

- animals should not empty food;

- you should organize different feeders for receiving dry and wet food. Drinking bowls for pigs are placed separately;

- liquid food requires an airtight container. Leaks worsen the microclimate of the pigsty, which negatively affects the health of animals and increases food costs;

- animals need to have unhindered access to food. It is preferable to use feeders with round or chamfered sides;

- so that the pigs eat all the food, it is worth purchasing an inclined structure. Then the food will be collected in one place.

The size of the container is also important:

- the dimensions should correspond to the size of the pigs: the piglet feeder will be much smaller than the design for adults;

- when growing large livestock, it is better to install an elongated trough. Then all the pigs can eat at the same time. Individual seats are separated by partitions.

The optimal width of the feeders is shown in the table. Dimensions are in centimeters.

| Age | Wet food | Dry food |

|---|---|---|

| Adult animals | 50 | 30 |

| Weaning pigs | 40 | 25 |

| Suckling pigs | 15 |

When feeding from longitudinal troughs, each animal must be allocated:

- about 50 cm for a boar;

- 40 cm for the sow;

- about 30 cm for piglets over 5 months old;

- 25 cm for piglets under 5 months;

- 15 cm for suckling piglets.

With this arrangement, animals constantly have access to food and do not interfere with each other.

How to make a do-it-yourself feeder

Today, livestock equipment is sold in all farm stores. However, most people still prefer to make feeders and drinkers for pigs with their own hands, adapting to their own needs. Everything that is at hand is used. How to make a pig trough at home:

From a plastic barrel or bottle

This is one of the easiest manufacturing methods. You don't even need a blueprint.

How to make a hog trough from a barrel:

- The container is cut with an electric jigsaw or other suitable tool into 2, 3 or 4 pieces in accordance with the original dimensions of the barrel.

- Legs made of wood are screwed to the side walls. They will ensure the stability of the structure.

- Sharp edges and burrs are treated with a sandpaper so that the animal does not get hurt.

The feeder is ready to use. Similarly, you can make it from a metal barrel.

Constructions made of 10 liter plastic bottles are suitable for young animals. To make them, you need to cut the vessel into 2 halves and remove the neck.

Metal feeder

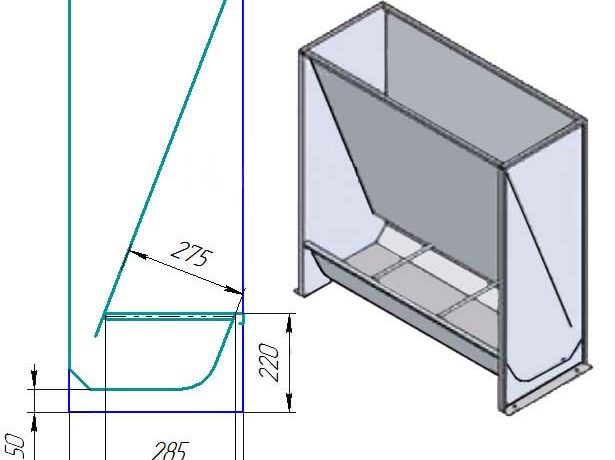

Hopper feeders for pigs are made from metal sheets. They consist of several parts:

- bunkers - a container for feed;

- pallet - accepts food from the bunker;

- tray - pigs eat from it;

- limiting strips - prevent overflow of the pallet;

- side fences - prevent feed from spilling over the sides.

Step-by-step manufacturing instructions:

- A profile pipe with a square cross-section (about 12 × 12 cm) is cut along the edge into 2 parts. This is the future tray.

- Two metal sheets (60 x 4 x 1.5 cm) are laid on a long side and welded at a distance of 7 cm using suitable metal cuttings. This is a pallet.

- The hopper is assembled from four sheets - 2 for the width of the tray and 2 narrower for the side walls. The end result is a conical parallelepiped.

- The hopper is connected to the pallet, then the tray is welded so that its center coincides with the edge.

- At the end, the tray is divided into sections for one piglet using reinforcement.

The finished trough is designed for 10 piglets. To make a structure for a different number of animals, a separate drawing should be developed.

Ceramic or asbestos-cement pipe

These structures do not corrode during use, therefore they serve for a long time.

Step-by-step instruction:

- A pipe of a suitable size is cut into 2 halves.

- Concrete supports are made according to its diameter.

- The transverse sections are cemented or plugs cut from the boards are installed in them. The seams are covered with mortar so that the structure is airtight.

- A metal grate made of reinforcement is placed on top so that the pigs cannot climb into the feeder with their feet.

The finished structure is installed in the pigsty.

From an old gas cylinder

This is a great idea for a reliable and durable structure. One feeder will last about 20 years.

Step-by-step instruction:

- Preliminary, gas residues, if any, are released from the cylinder. To check, the outlet is smeared with soapy foam. The appearance of bubbles will indicate that there is gas inside.

- The balloon is overturned on its side. Using a hacksaw for metal, cut the valve. In the process, sparking should not be allowed. Better to ask another person to water the cut with water.

- After that, the gas cylinder is thoroughly washed, be sure to rinse the walls.Water is poured away from home, because the smell of propane is very persistent and does not disappear for a long time.

- The cylinder is cut into equal or different parts depending on the purpose of use. For feeding adult pigs, two identical halves are suitable. You can make one of them larger and the other smaller. The latter will make a trough for small piglets.

- To prevent the pigs from climbing into the container, transverse partitions from the reinforcement are welded on top.

The finished feeder is securely fixed to avoid tipping over.

Drinking bowls for pigs

In addition to feeders, drinking bowls are required for organizing a pigsty. In the past, farmers used troughs or basins, but the animals constantly overturned them. Because of this, the floor was covered with fetid dirt.

Modern pig drinkers also differ in the type and method of water supply. Livestock breeders buy them in specialized stores or make them themselves.

The most common option is the cup design. It is a container with sides that prevent animals from spilling water.

It is of two types:

- valve - when the pig approaches the drinker, it steps on the pedal. As a result, a mechanism is triggered and water enters the bowl. If the pig moves aside, the liquid will stop pouring;

- nipple - to get drunk, the pig takes a special nipple into its mouth, from which water comes. The design has a complex mechanism, but it is more economical than the first option.

Both types of piglet drinkers can be made by hand. The valve design is the simplest in execution.

Benefits of automatic feeders

This useful invention makes the task of farmers much easier. Automatic structures are designed for dry feed. They work according to a simple principle:

- feed is poured into the upper tank, from where it enters the lower trough;

- as the food is eaten, space in the pan is freed up and replenished with food from the top.

The pig feeder has several advantages:

- the pigs are provided with food for a couple of days in advance;

- new feed is not delivered until the pigs have eaten the previous one;

- animals cannot climb into the container and scatter food around the pigsty.

A well-organized feeding system will help to raise healthy and strong livestock. Each pig will receive a sufficient amount of food, and the pigsty will remain orderly and clean.