Content:

A hand-made plywood hive saves on housing costs for bees. In addition, the plywood version is lighter and easier to transport than the one made from wood. There are several assembly options, one of which involves the use of foam. It is possible to make different types of this product: nucleus, Dadan, lounger or multi-level structure.

DIY plywood and foam beehive

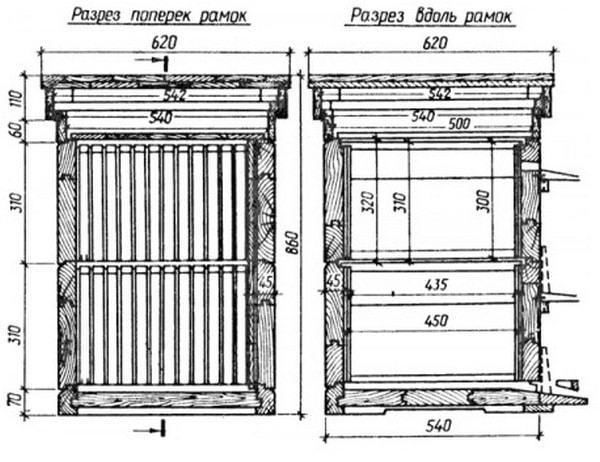

It is possible to make a hive from plywood and polystyrene independently. Before starting work, you should decide on the design, draw a drawing and prepare the necessary tools and materials. Below is a diagram of a 12-frame hive, which consists of two buildings. Dimensions inside: length and width - 450 mm, height - 310 mm. Material thickness affects the dimensions of the outer casing.

Steps to make a hive with two bodies:

- Take 12 parts that have dimensions of 450x310 mm. For the walls, take 4 fragments of 450x306 mm. The thickness of the material should be 8-10 mm.

- The hive elements are connected using wood glue. On one edge, all parts should match, and on the other edge, folds should form on the front and back walls. They are needed to position the frames.

- Make a gap under the notch, which is at the top. It should be 15 mm in diameter.

- For the tap hole, which is located below, make a rectangular hole, the dimensions of which are 250x5. It is made when the bottom of the hive is not removable.

- To install the housings, recesses are made on parts of the blocks. They overlap each other.

- Then the bodies are collected. For this, the parts are coated with glue and fixed with self-tapping screws. In addition, it is possible to use corners and brackets, which are located along the perimeter.

- In accordance with the dimensions of the body, the lower box is cut out. Its bottom is covered with plywood, which must be resistant to water. The joints are coated with glue and additionally secured with self-tapping screws.

- The removable bottom is made in accordance with the drawings. A body is made on top of it.

How to assemble the roof of the hive:

- by the outer dimensions of the body, its area is determined;

- the plates are installed in the same way as the body elements are fastened;

- with the help of glue and self-tapping screws, a sheet of plywood is installed on top of the structure.

Next, they make an arrival board and attach it at the entrance. Handles are glued from layers of plywood and attached to the walls of the case. To make the plywood hives last longer, they impregnate all surfaces of the structure with a water-repellent liquid. All elements are collected when the liquid is completely dry. There are frames inside.

The assembly of other types of hives is carried out in a similar way. The thickness of the plywood affects the climate inside the house. Insulation of hives is carried out using foam plastic having a thickness of 50 mm. It will protect bees from wind, dampness and cold. Such insulation allows insects not to expend additional energy for heating, due to which the feed is consumed in a smaller volume.

How to make a beehive lounger out of plywood and foam

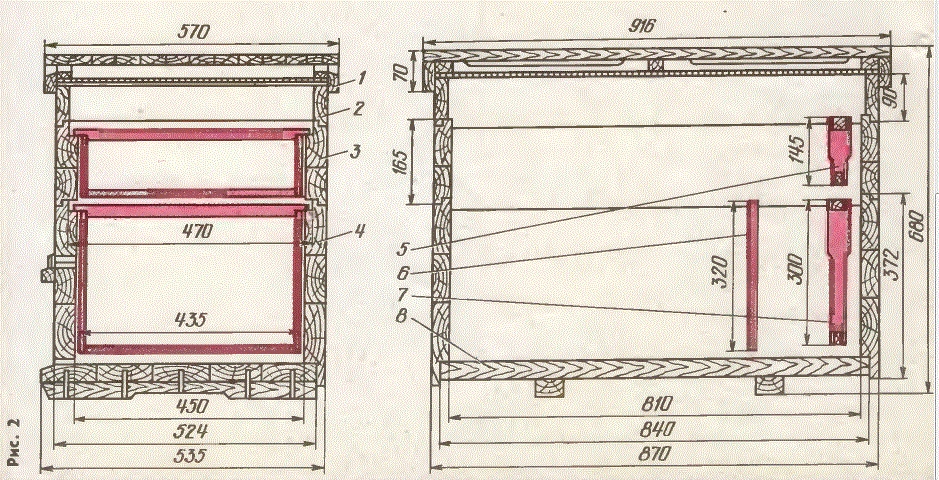

A lounger hive is a type of bee house that is most suitable for beginners. Inside a house of this type, 16 or 20 frames are usually placed. If the lounger is made by hand from plywood, then its walls are insulated with expanded polystyrene.

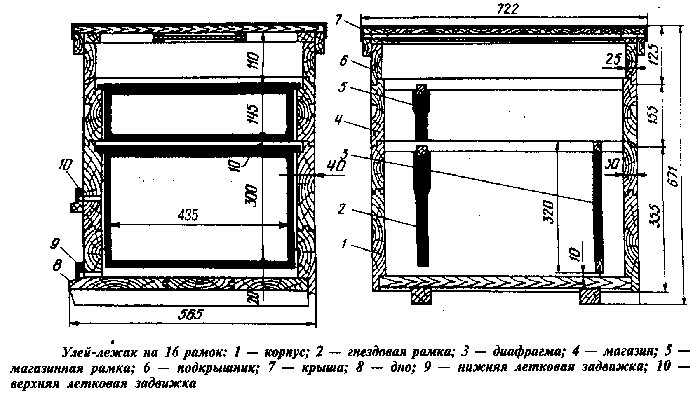

A plywood and foam lounger can be made using the drawing below.

1 - roof;

2 - roof liner;

3 - shop;

4 - case;

5 - shop frame;

6 - diaphragm;

7 - nest frame;

8 - bottom.

Dimensions of the beehive-lounger:

- front wall: height - 87 cm, length - 37 cm;

- back wall: height - 87 cm, length - 44 cm;

- right and left wall: height - 49 cm, length - 44 cm.

To make a plywood deck chair hive you will need:

- Prepare blanks.

- Attach the back, front and side walls to the bottom.

- The back and sides should fit snugly against the bottom. To make the lower entrance in the hive, the front part is attached to the bottom above at a distance of 1.5 cm.

- Assemble the roof and cover it with water-repellent material (eg sheet metal).

- One or several entrances are made from above. Their shape can be rectangular or round.

To make a 16-frame hive, you can use the technology described above. It is possible to install up to 20 frames in a finished hive. Below is a drawing in order to make a 16-frame bee house.

Varieties of plywood hives

Plywood hives are popular with beekeepers. The material used is convenient and reliable in use. Foam models are especially widespread, in which the walls are insulated with foam. These houses are warmer than the wooden version, in addition, they are much lighter, which is very convenient for transportation.

Plywood is an environmentally friendly material. It consists of several layers of wood fibers.

Thus, plywood has the following advantages:

- heat;

- dryness;

- strength;

- ease;

- comfort for bees inside the house;

- cheapness and availability of material.

There are the following types of hives:

- Beehive lounger. Most popular among Russian beekeepers. It looks like a horizontal box. Its lid is hinged or put on. Inside there is space for several frames. There is a 4 summer house. During manufacturing, not only nails, but also PVA glue are suitable for fastening the parts. Plywood boards for this type should not be thin. It is best that the boards are made of birch as it is strong, dry and warm. Be sure to insulate the walls with plastic for this type. Bee hives are also divided into several types: Vladimirsky (has a large capacity), standard (you can place 16, 20, 24 frames), Polish (designed for 20 frames).

- Double Wall Hive: Has two walls that are made of wood. It is important that the outer wall is thicker than the inner one, since the cold, passing through it, will linger between the side parts, which will cause moisture inside the house. The outer wall can be painted for added protection. In cold regions, double-walled options are widely used, since they protect insects well from frost.

- Multi-body option. In another way, it is called the Alpine type. This species reproduces the natural habitat and resembles a hollow tree. This type is compact and suitable for apiaries with a small area. There are no partitions inside, which is more convenient for bees. The structure of the house can be easily assembled and disassembled. They are also very convenient for keeping large numbers of bees. The plywood sheet must be at least 18 mm thick. This species can be operated up to 10 years. When making a multi-body view from plywood, it is better to fill fiberboard outside.

- Dadan's look: simple design, easy to maintain and more spacious. In this type, 12 frames can be placed, each of which has access. If the bee colony is growing, it is easy to add hulls. More suitable for inexperienced beekeepers. The main disadvantage: the overall frame.

- Hive Ruta. Has 6 buildings. There are 10 frames in each case.As the bee colony grows, the number of boxes can be easily increased. It is also easy to remove the case if there is no need to use it. However, for a cold climate, this type of houses is not suitable, since the constant rearrangement of bodies and frames can cause hypothermia and various diseases in insects.

- Cassette or pavilion - room on wheels. There are narrow and tall cabinets inside. Families live here in drawers that slide out. This species will best protect insects from diseases, as they are well protected from moisture and dust. It has two walls: the outer wall is thicker than the inner one. This design allows the bees to create their own internal microclimate.

For making a bee house, plywood is the best option. It has several advantages over other types of material. It is possible to make a wide variety of types of hives from it. Compared to the wooden type, plywood hives are lighter and easier to transport.

You can also use an active hive to make an incubator with your own hands. To do this, you just need to put a thick metal mesh on top of the frames so that bees cannot crawl through its cells.