Content:

Snow removal is a task that a snow blower with a walk-behind tractor will help to cope with. This type of attachments for a walk-behind tractor is popular with buyers. With the onset of winter, many are thinking about which snow blower to buy, and are looking for information on how to remove snow with the help of motor vehicles, which they are used to using in the summer for the garden.

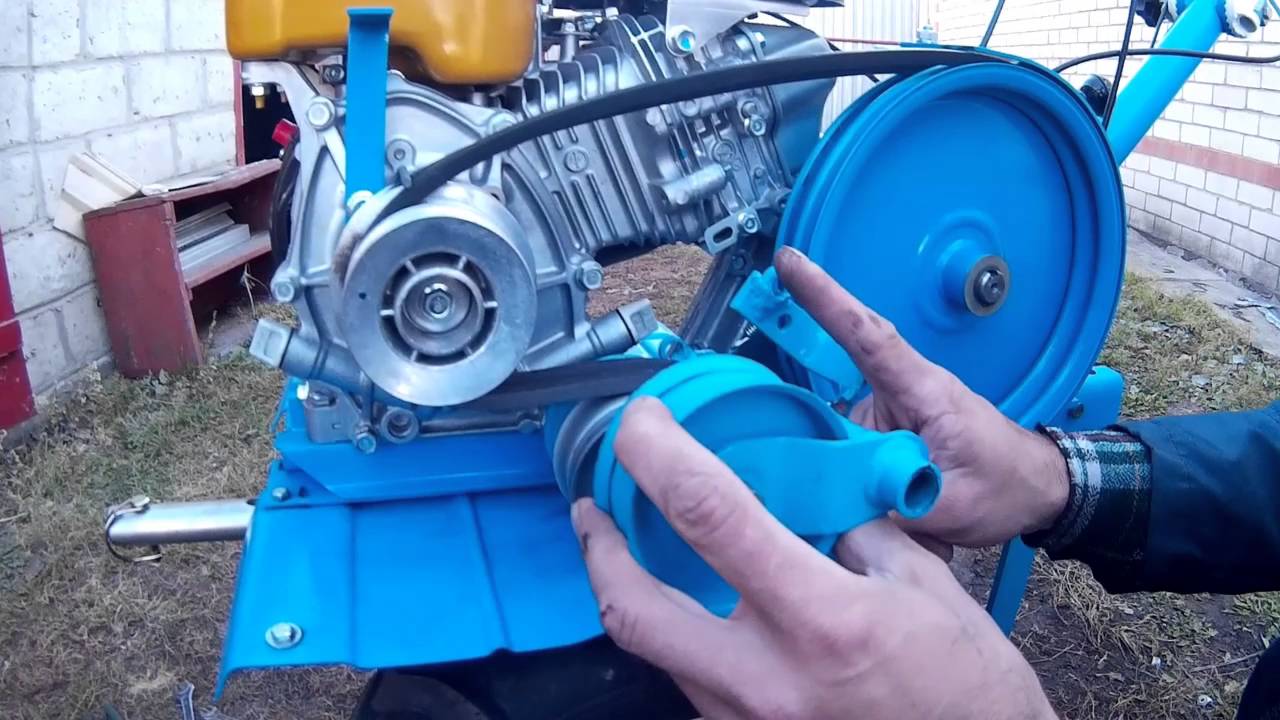

Construction of the "Neva" snow blower

The arrival of winter is marked not only by a sharp change in ambient temperature, but also by the fall of a large amount of snow. This becomes the concern of utilities, owners of private houses and country cottages, because the snowdrifts interfere with the passage of cars and the free movement of people. The Neva snow blower is especially popular among small-scale household equipment. This walk-behind tractor can be aggregated with a large number of attachments and trailed equipment. Snow blower MB-2 "Neva" is an excellent assistant when clearing snow in a small area.

Attention should be paid to the process of cleaning engine motoblocks and cylinder heads. This is as important a procedure as the processing of a device equipped with a special drive. The compact snow plow attachment to the Neva walk-behind tractor is responsible for the rotation of the auger mechanism.

The drive train is equipped with 2 stars. They are divided into master and slave. It is not possible to perform a thorough inspection of these parts if the parts are dirty, oily, paint or corroded. Checking for cracks in cast iron devices and walk-behind tractors requires initial surface cleaning. Thus, magnetic particles can be detected. The next stage of testing is aluminum castings.

The snow blower for the Neva walk-behind tractor is a wheeled or caterpillar type machine. The equipment is equipped with a working screw, which, when rotating, moves the snow inside the unit, which is then thrown out in a certain direction under the action of a powerful air jet.

The snowplow is divided into two types:

- Non-self-propelled.

- Self-propelled.

Device Specifications

Modern designs are perfect for clearing soft and loose snow. The SMB snow blower for the Neva walk-behind tractor is an indispensable device for cleaning paths. With the help of such a unit, you can clean underground passages, small areas in the country and pedestrian sidewalks. Much physical strength is required to move it.

Non-self-propelled snowblowers, as a rule, are equipped with electric or gasoline engines of relatively low power (from 3.5 to 5 hp), while they are capable of throwing snow at a distance of 3 to 5 meters.

Device characteristics:

- Snow blower drive chain in casing.

- Weight - 50 kg.

- Snow throwing range - 5 m.

- Coverage 0.65 m.

A snow blower for a walk-behind tractor is a mechanical tool. The unit is produced complete with walk-behind tractors of various modifications, it is used for snow removal in low-contour areas. Auger snow blowers throw snow through the bell to the side within +/- 95 degrees from the direction of movement of the walk-behind tractor.

There are also single-stage mounted snow blowers on the market.With the help of these developments, it is possible to clear the snow due to the rotation of the augers driven by the motor of the walk-behind tractor. The throwing distance is 3-5 meters.

The principle of fastening the Neva snow plow

The snow blower cuts into the snow and clears the road effortlessly. It can handle 12 m3 in one minute. The mass ejection speed is 70 km / h. At this speed, the snow thrown out of the disposal pipe falls very far from the cleared road.

Getting started, a novice inventor needs to solve several organizational issues:

- What type of engine to choose: electric or gasoline.

- Decide on the type of snowplow.

But if the snow blower is planned to be used in all corners of the settlement, then you need to choose a gasoline engine.

To choose a snowplow, you need to know what types of it exist and what they are used for:

- Snowmobile bulldozer. Works with the front blade. Convenient for cleaning stale and cohesive snow.

- Snowmobile fan. Throws away the snow mass with blades (with the help of their work, the snow rises and falls into an inclined pipe, from which it flies out and spreads far from the cleared area).

- Auger snowmobile. The snow is picked up by the auger and falls into the pipe opening, from where it is thrown out.

- Snowmobile vacuum cleaner or air blower. It works on the principle of sucking up stuck snow and quickly throwing it out of the harvester from the opposite side.

How to assemble a snow blower

DIY snow blower assembly sequence:

- First, a box of iron sheets is taken, the ends of which are bent like skis. To make a shaft, you need to get a pipe with a thickness of at least 5 cm. A grip is welded in the box, made of two welded bent plates in a U-shaped way. Both plates must be rotated 180 degrees in relation to each other.

- The auger can be made by hand using a conveyor belt (1.5 m in length and 10 mm in thickness). It is possible to cut 4 rings from the tape using a jigsaw (28 cm in diameter). In the absence of such a device, it can be replaced with a special board, which is used like a compass (rotations in a circle). With this manufacturing method, quality rings are obtained.

- In the casing, made of galvanized iron, you need to make a hole, and then install a pipe in it, which will serve as an ejection of snow. The holders on both sides of the spreader are welded to it.

- A gear or pulley must be installed on the auger drive shaft (the choice depends on the drive). Rings on one side are cut and welded to the beginning of the other end. One side of the workpiece is welded to the gripping blade, and the other end, reinforced with a strip of steel, is welded to the shaft at a distance of 5-10 cm from the free end.

- Next, you need to prepare the auger drive. It can be either chain or belt. A belt drive should be used when the engine has a pulley, and if the auger jams during operation, the belt will slip safely. The gripper body should be 2-3 centimeters larger than the pulley. In this case, the pulley will not cling to the body, there will be a gap between them.

- To prevent the auger from breaking, it must be equipped with a spare pin that breaks off in the event of a jam. A round hole is made behind the gripper, into which a bent pipe of the required caliber is inserted and welded.

- After carrying out all the work, you must carefully check that the distance between the gripper blades and the rear wall of the box is minimal.

- The glasses should be fixed on the sides of the box.It is better to create glasses from AMgb aluminum and fasten them to the machine with MB bolts (be sure to tighten with nuts). The shaft rotates in bearings located in glasses. He should look out of the box at a distance of 5-10 cm.

- The swivel gutter can be made from a sewer pipe (160 mm diameter). A groove is attached to this pipe, which sets the direction for the snow. The diameter of the chute should be larger than the width of the auger plate, which is responsible for the discharge of the snow mass.

- At the end of the shaft, an asterisk is welded to change speeds. The sprocket and shaft are connected to the walk-behind tractor using a chain.

- The rotor is connected to the front wall of the body by means of rivets with a diameter of 4 mm. If skis are installed on the unit, then wooden blocks can be attached under them or plastic strips can be screwed on.

- Make a frame from steel corners (50 * 50 cm). Angles measuring 25 * 25 mm are attached to the transversely installed corners. The power unit is attached to them.

- The handle of the machine is bolted to the longitudinal corners.

After the assembly is completed, the walk-behind tractor can be spray painted.

In addition to the main technical parameters and characteristics that affect the quality and performance of snow blowers, you should consider some additional devices that can make the operator's work more comfortable. The standard equipment of models of snow removal equipment can be supplemented with a number of additional functions, for example, a heating system for the handles of the machine, an electric starter, a headlight for operation at night, etc.

In conclusion, it should be noted that the snow blower makes it possible to adjust the direction of snow throwing using the screen rotation, but the snow throwing range is adjusted by rotating the device motor.