Content:

The manual seeder is a convenient and simple sowing unit used by small farmers, owners of summer cottages and household plots. Having simple settings and used for sowing vegetable and grass crops, it can be either purchased in a specialized store or made independently.

Description

The simplest single-row manual precision seeder consists of the following parts:

- Funnel-shaped seed hopper with a capacity of up to 1 liter (1-1.5 kg);

- 2 supporting drive metal wheels with lugs, with protrusions 1-3 cm high;

- Sowing sleeve (drum) with holes 3-5 mm in diameter, located on the same shaft with the drive wheels;

- Wedge-shaped opener;

- Tubing attachments for the handle to be screwed into the front of the seed hopper.

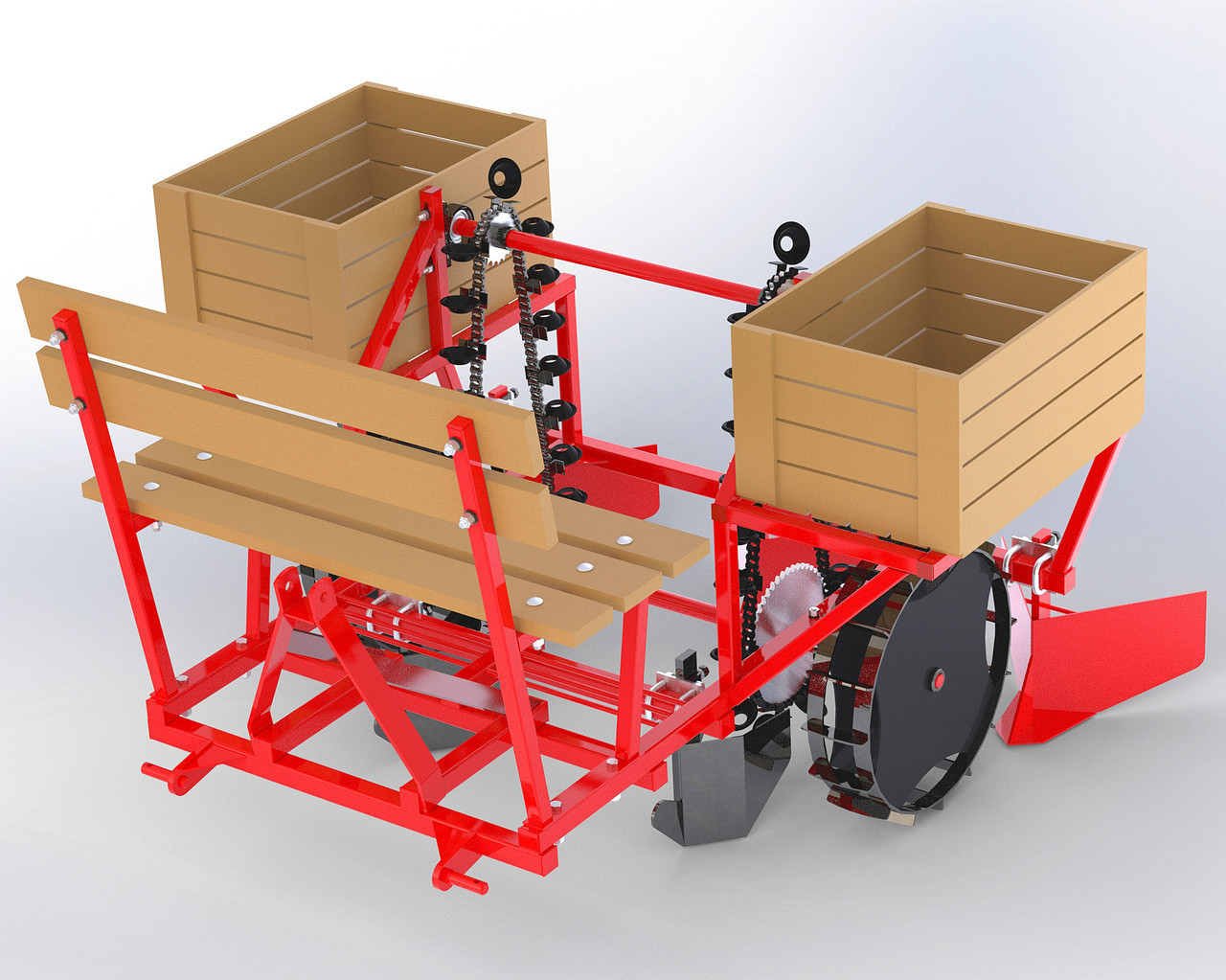

In addition to such a simple design, there is also another, more accomplished and reliable one. The single row model of such a seeder consists of:

- Rectangular frame;

- Seed hopper with a volume of up to 2 liters with a tight-fitting lid;

- The sowing unit is a bushing mounted on a shaft with a sprocket for a chain drive. In this case, the size of the holes on the sleeve range from 3-4 to 16-18 mm;

- A coulter with a harvester installed behind it to fill the groove with seeds laid in it;

- Front drive wheel;

- Drive chain mounted on the sprockets of the front wheel and seeding unit;

- A wide rear press wheel with a bracket to clean it of dirt and adhering wet soil;

- Marker for adjusting the row spacing;

- Forked handle with length adjustment.

Such seeders are used to sow vegetable crops such as:

- Eggplant;

- Peas;

- Bow;

- Carrot;

- Cucumber;

- Pepper;

- Parsley;

- Radish;

- Beet;

- Tomatoes;

- Beans.

Also, with the help of such seeders, you can sow melliferous grasses in rows: alfalfa, sweet clover.

Among the types of manual seeders described above, the former are used for sowing small beds of small-seeded crops in greenhouses and greenhouses, while the more productive latter are used for sowing large-seeded vegetable crops in open ground.

Principle of operation

A mechanical precision seeding seeder of the simplest type works as follows:

- A sowing sleeve with holes for a specific crop is installed on the drive shaft

- Seeds are poured into the bunker;

- Using a marker (for the second type seeders described above), the row spacing is set

- The seeder is installed at the beginning of the first row of the sown area;

- The seeder is set in motion by smooth and jerky movement;

- The process of sowing seeds, hidden from the human eye, is as follows: each seed fits tightly into the hole in the sleeve, then when it rotates, it falls into the groove made by the harrow, and is filled up.

- If there is a press wheel at the rear of the drill, installed exactly in the center of the sown row, the soil above the seeds is carefully compacted. This improves the contact of the seed material with the soil, accelerates its germination, the absorption of nutrients and moisture by the sprout and its root system

- When working with such a machine, the sower must periodically check the amount of seeds in the hopper, filling it with new ones if necessary.

- After sowing is complete, the remaining seeds are poured out of the hopper, the sowing sleeve, opener, harrower, support wheels are removed and cleaned. The drive chain and sprockets are periodically lubricated with special grease

Specifications

The manual precision seed drill has the following characteristics:

- The number of seeding units (rows) - in modern models, it ranges from 1 to 5-7;

- Sowing device type - sleeve or brush;

- Type of harrow - most of the manual seeding devices are equipped with plate harrow;

- Opener type - wedge-shaped (frontal);

- Capture width - in multi-row (2 or more seed drills) this characteristic is on average 7-8 cm. In single-row units, the row spacing is adjusted by changing the marker length and can be up to 50-60 cm;

- Seeding depth - from 1 to 5 cm;

- Capacity (volume) of the seed hopper - the seed hopper of various units can hold from 0.4-0.5 to 2 liters of seed;

- The type of rotation transmission from the drive wheel (wheels) to the seeding device is direct (the seeding devices are located on the same axis with the drive wheels) or chain (the seeding device is connected to the drive wheel by means of two sprockets and a chain);

- The recommended speed of the seeder is 3-4 km / h;

- Productivity - from 2-3 to 10-12 acres / h.

Adjustment

In manual seed drills, before sowing, the following settings are made:

- Seeding rates;

- Seeding depth;

- Row spacing.

These settings are very important for good planting.

Seeding rate

The seeding rate accuracy on different types of metering devices is regulated in its own way:

- In sleeve-type sowing devices, the seeding rate is regulated by the selection of the sleeve with the corresponding holes and the pitch between them;

- In brush metering units, the seed rate is adjusted using a perforated calibration disc. The seeding rate is regulated by setting the corresponding hole on the calibration disc opposite the exit window of the sowing device.

Embedment depth

The seeding depth is adjustable in the chain-driven seeders of the seeding unit. The adjustment process is as follows:

- The seeder is installed on a level surface;

- A plank with a thickness equal to the planned sowing depth is placed under the rear press wheel;

- Using the adjusting bolts, the coulter is lowered until it touches the floor. In this case, it is not the tip of the coulter that should touch the floor, but its entire lower plane.

Row spacing

The row spacing is adjusted by changing the distance between the metering units or lengthening the marker. The latter option is more convenient and allows you to make large aisles when sowing, for example, a crop such as corn.

Manufacturers

Among the manufacturers of manual seeders, the most famous brands are:

- "GROWTH";

- "GARDENA";

- "SOLO".

Seeder manual do it yourself

You can make a homemade precision seeding seeder with your own hands using the following technology:

- A seed hopper of the required volume with a lid is made of tin;

- In the lower part of the hopper, a hole is made for the shaft of the seeding unit;

- Outside the hopper, two bearings are welded on both sides. They are welded in such a way that the center of their inner diameter coincides with the center of the hole for the shaft of the seeding unit.

- A sprocket is welded to the metal axle 4-5 cm longer than the seeding wheel. On the other side of the shaft, a hole is made for a stopper - a cotter pin.

- A seed box with opener from an old pneumatic seeder is attached to the bottom of the hopper;

- A rectangular frame with two crossbars is cooked from a corner or plates. The short end faces are not welded.

- A comfortable two-horned handle with length adjustment is welded to the frame;

- In front of the frame, a wheel from a bicycle is mounted - a clamshell with an asterisk;

- A wide metal wheel is attached to the rear of the frame;

- The hopper with seed box and opener is welded to the frame cross members;

- Seeding bushings with holes for various crops are made from a round cross-section of ebonite or dense plastic blanks. A hole of the same diameter as the driven shaft with an asterisk is drilled in the center of the resulting sleeve.

- The sleeve is inserted into the neck of the hopper, a shaft with an asterisk is passed through it, which is locked with a cotter pin from the outside;

- A chain is put on the sprockets of the sowing device shaft and the drive wheel;

- Before starting work, the chain and sprockets are lubricated with special grease.

The manual seeder for vegetables and small seeds (grass and lawn mixtures) is a handy device that will greatly facilitate the sowing company both in a small area or in a greenhouse, as well as in medium-sized areas where there is no access for tractors. Any family member, even a teenager, can use such a seeder. It has no dangerous moving parts and is easy to set up and not time-consuming. Such a technique is economically advantageous - each vegetable grown with its use will have lower labor costs and cost, compared to manual sowing.