Content:

The manufacture of a mini tractor for household and farm use makes it possible to greatly facilitate the performance of many types of work, and also makes it possible to use it as a vehicle. The article describes in detail how to make a homemade mini tractor and everything to it.

Making a homemade mini tractor

In a private house, on a plot of land and in a field, the owners have a lot of work. The use of small-scale mechanization means can provide significant assistance. Usually we are talking about using:

- simple mechanical homemade devices;

- devices operating on the basis of an electric motor;

- walk-behind tractor;

- mini tractor.

Although, at first glance, it may seem that making a tractor yourself is a very difficult task, in fact, making a mini-tractor is quite realistic. To do this, you need to choose a suitable design and use not only homemade parts and assemblies, but also purchased ones.

Further, the process of self-creation of such a machine is discussed in detail.

Mini tractor design

In order to design and assemble a simple and reliable mini tractor, the first thing to think about is the motor that will power it. It is important to bear in mind here that the power plant is needed not only for the movement of the tractor, it will become an important help in ensuring the operation of the attachments.

The base on which the structure should be supported will be a metal frame. The undercarriage of the tractor is four wheels on two axles.

A large number of attachments useful in the household is one of the most important reasons for having a mini tractor. The design must necessarily provide for the use of a three-point hitch, which is necessary for the reliable connection of additional devices.

What is a mini tractor

The following is a description of the basic mini tractor systems for the farmer or private home owner.

Engine selection

You can use an engine from an old passenger car. It can be VAZ, GAZ, Oka or Zhiguli. If the farm has a walk-behind tractor, then its engine can also be used for this purpose. In order to reduce noise during operation, use a homemade muffler for a mini tractor. You can also use a hydraulic device.

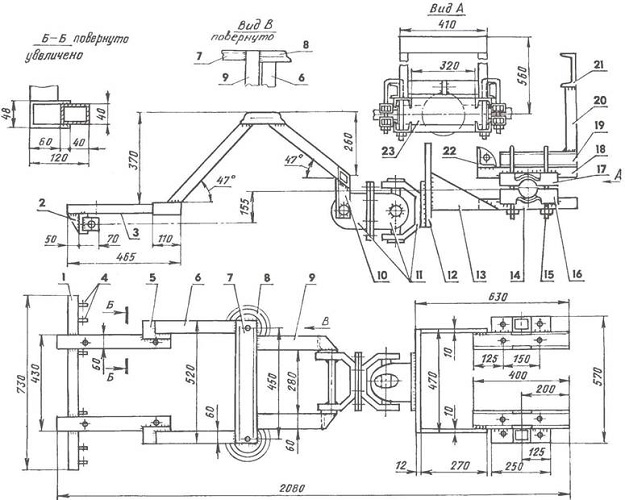

Frame

When creating a frame, you need to use a profile tube. A rectangular structure can be welded from it using a cross member, it will become the basis for a tractor. The dimensions of the mini tractor frame are selected in accordance with its design.

There is another manufacturing option, which is called a "breaking frame". It consists of two smaller frames that are connected by an adapter.

Such a frame is beneficial to use with all-wheel drive tractors, which have a home-made front drive axle for the mini tractor in addition to the rear.

When choosing how to make a frame for a mini tractor, you need to take into account its size and design features.

Chassis

When installing the chassis, you need to install wheels, transmission, front and rear axles with hubs.

When choosing wheels, it is necessary to take into account the tasks for which the tractor is manufactured. If this is done to solve transport problems, wheels with a diameter of about 40 cm will do. If it is necessary to work in the field, then it makes sense to use larger wheels to increase the cross-country ability.

Usually only the rear axle is made leading. It is taken ready-made from a passenger car, for example, from a UAZ or Moskvich. In this case, the front beam on the mini tractor is made by hand.

If there is such a need, a homemade gearbox for a minitractor can be made.

Installation of hydraulics

The hydraulic system is necessary when creating a mini-tractor in order to ensure its controllability. This is necessary for the following reasons:

- The tractor, which is equipped with hydraulics, is easy to operate. In this case, the steering wheel can be turned almost effortlessly, even with one hand.

- The hydraulic drive makes it possible to ensure the operation of various attachments.

- With this system, the brakes will work almost instantly.

You need to understand that some of the engine power will be spent on hydraulics. Therefore, it is not customary to install it on a machine if a low-power motor is used.

Do I need a PTO

This working unit (PTO shaft) plays an important role when using a mini-tractor. As you know, its application mainly consists in transportation or for the use of various attachments, some of which require an engine to operate.

When using the PTO shaft, the engine power will be transferred to the hitch.

There are two main types of PTO:

- Dependent, in which rotation is transmitted from the movement of the wheels. In this case, as soon as the tractor stops, the PTO stops rotating.

- In the independent version, rotation is based on the operation of the motor and will continue even if the tractor is not moving.

If you are looking for which hydraulic motor is better to put on a homemade mini-tractor, then you can use it from the OPK or from the SZD motorcycle.

Making a three-point hitch

This knot is very important for this design. The fact is that any attachment must be securely connected to the tractor in order to do its job. This node is just designed for this.

For quality work, it is necessary to ensure the mobility of this unit both horizontally and vertically. Horizontal free play is important when making turns, vertical will allow you to install the nozzle in the lower (working) or upper (disabled) position.

Usually, for the manufacture of this unit, parts are taken from old agricultural equipment.

Selection and installation of brakes and clutch

In order for the tractor to have brakes, it is recommended to take those that are used at UAZ. The brake pads will need to be installed so that they are on the wheel rim. To control them, one of two options is used:

- pedal;

- lever arm.

They are installed in the driver's cab.

As a clutch system, you can take a ready-made one, which is intended for use on UAZ or Moskvich. The gearbox to which the clutch needs to be attached is also taken ready-made from a car.

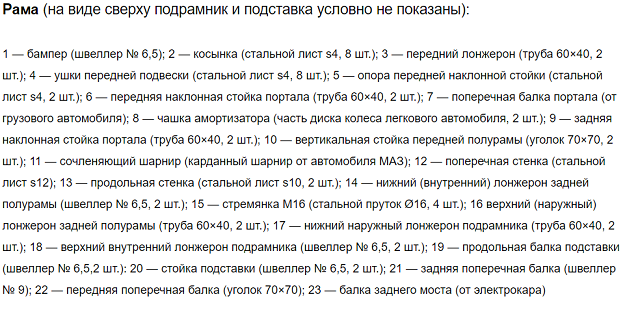

Steering installation

Building a rudder can, in principle, be done on your own, but it is a rather complicated job that you can still do without.

Choosing a trailer

There are usually two main types of trailers:

- Semi-trailer trolley. The tractor carries her along, transporting useful loads.

- A dump trailer for a mini tractor is also used. It lifts the bottom on one side, which makes it easy to unload the dump trailer.

It's quite possible to make a dump trailer for a minitractor with your own hands, but you can also purchase it.

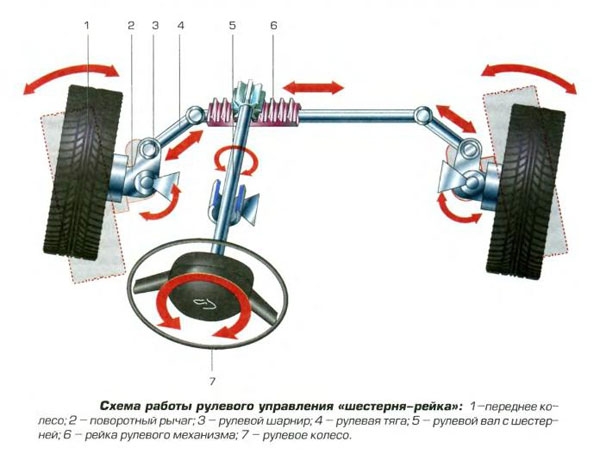

Selection and manufacture of the cabin

Although a self-made tractor may well, it seems, do without a cab, however, in winter, its need becomes obvious. Working for several hours in the wind and frost is quite difficult.

This drawing shows typical dimensions. Before working on the creation of the cab, it is necessary to adjust them to the dimensions of a particular mini-tractor.

Step-by-step manufacturing algorithm:

- At the first stage, a wooden frame is made from wooden slats, which will be the basis of the structure.

- The profile metal pipe is cut exactly to the dimensions of the wooden parts.

- Metal parts are connected by welding.

- It is required to weld glass holders in the right places. This is done by placing the welded structure with a roof on the ground.

- The upper part of the cab (roof) is made of 1 mm steel sheet. The floor and sides are made of 2 mm steel. You can cut steel using a grinder.

- The door frame is made from a profile pipe.

- You will need to use a device in order for the doors to close automatically, as well as to lock them.

- From the inside, the cabin is laid with foam rubber and covered with leatherette.

- Then the structure is welded to the frame.

How to make a homemade mini tractor

For its manufacture, it is necessary to decide for what work it is intended. Then you need to think over the drawing and buy the necessary purchased parts, of which there are quite a few in this design.

After that, you need to make and assemble the tractor, in accordance with the existing drawing of the mini tractor.

Suspended equipment types

A hitch for connecting additional equipment can be made at the front or rear of the tractor. In the first case, this is necessary for devices that are attached in front of the tractor (for example, a blade), in the second - for those that must be attached to the rear (these can be, in particular, harrows, rakes or mowers).

Making your own mini-tractor is difficult, but a very real task. It is useful for automating time-consuming household and farm work.