Content:

Chopping firewood is hard physical labor, especially when it comes to harvesting firewood for a private house heated by stove heating. In this case, in order to provide yourself with firewood for a long time, it is necessary to chop a sufficiently large number of logs. Not everyone can do such work, so it is worth thinking about ways to mechanize chopping wood.

Mechanical devices for splitting wood are called wood splitters. There are many different types of them, which differ in their principle of operation, the method of installing the log, power, method of feeding and many other parameters. And, of course, depending on all these parameters, the prices for industrial wood splitters are also very different.

Design features of the rack and pinion log splitter

Some of the easiest to use are wood splitters. Their simplicity of design, combined with a relatively low price, makes them one of the most popular wood splitting devices for domestic use.

They are mounted on a strong base on which the cleaver is fixed. There are two modifications of the cleaver allowing to split the workpiece into two and four parts, respectively. The engine driving the mechanism can be gasoline or electric. The main structural difference of rack-and-pinion wood splitters is the presence of a toothed rack and gear, with the help of which the pusher moves the workpiece to the cleaver.

Operating principle

The engine rotates the gear using a belt drive. When you turn the control handle, the pinion sets the rack in motion. The rack, moving along the guides fixed on the bed, pushes the pusher forward. A workpiece is located on the bed between the cleaver and the pusher; as it moves, the pusher splits the workpiece against the cleaver.

After the push rod reaches the end, the rack and pinion are disengaged and the entire mechanism is restored to its original state. On some wood splitters, the rail is returned to its place manually - by the reverse movement of the control handle. After discarding the resulting firewood and replacing the workpiece, the whole process is repeated anew.

Main advantages of wood splitter

When choosing a household rack and pinion wood splitter, you should pay attention to the following parameters:

- weight and dimensions;

- generated effort;

- engine power;

- maximum workpiece length.

Due to their simple design, rack and pinion splitters are quite reliable, and their repair is not difficult and rarely requires contacting specialists. Almost all parts can be purchased at the store.

Many domestic wood splitting machines have the power and performance of industrial equipment. At the same time, rack and pinion wood splitters are quite economical and do not require special operating conditions.

Disadvantages of wood splitters

The main disadvantage of the rack and pinion wood splitter is the limited distance between the pusher and the cleaver. This leads to the need to saw the logs into pieces of the desired size.

Operating rules

The operation of domestic wood splitters is quite simple and does not require special knowledge and skills. They are suitable for operation almost all year round under any temperature conditions. To maintain it in working order, it is enough to periodically lubricate the rotating mechanisms and periodically clean the rack. These actions take a minimum of time and do not require disassembling the mechanism.

Review of the best models of wood splitter

Over the past few years, many companies have launched the production of various models of household firewood cutters of various types and modifications. Most often, you can find wood splitters manufactured by two companies on sale: Artmash and SPRINT. Below is an overview of several models for solving different problems.

If you need to chop small workpieces and you need a wood splitter with an electric drive, powered by a 220V network, then a wood splitter manufactured by Artmash with a 2.2 liter electric motor is perfect for this. from. and a generated force of 12 tons.

With a supply voltage of 380V and the need to chop larger workpieces, you should pay attention to the SPRINT wood splitters with a 3 liter engine. with., if the engine power does not play a fundamental role, then it is better to consider the model of the Artmash company.

The same principle applies for gasoline and mixed drives. Almost all manufacturers use 6.5 liter gasoline engines. with., while SPRINT wood splitters are focused on splitting larger workpieces, and for simple household needs Artmash rack and pinion wood splitters are more suitable.

Do-it-yourself rack wood splitter

Buying a factory-made model may not be affordable for everyone, so many are trying to solve the issue of mechanizing the process of harvesting firewood with their own hands. Due to a fairly simple design, with certain knowledge and tools, making a rack and pinion firewood splitter with your own hands is not an insoluble task.

Most often, an electric or electromechanical option is chosen for the manufacture of a rack and pinion wood splitter at home. In the second case, the movement of the rack takes place using a flywheel. This choice is due to the fact that electricity is the most accessible and cheapest source of energy.

Rail, shaft for wood splitter

To make a rack, you can use a shaft by cutting teeth in it in accordance with the existing gear. What is a wood splitter rail suitable for? You can use the toothed racks from the automatic gate lifting mechanism, you just have to cut off the workpiece of the required length from them.

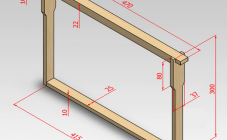

Stanina

The frame can be welded from a channel, I-beam or profile pipe, as a cleaver, you can weld an ordinary ax to the frame or make it from thick sheet iron.

Activation mechanism

The switching mechanism can be purchased separately or made by yourself. This requires a return spring and a control handle. When the control handle is pressed, the rack is pressed against the gear, with the reverse movement of the control handle, the rack is unhooked from the gear and returns to its original position.

The rack splitter is the simplest, most reliable and inexpensive wood splitter for domestic use. The reliability of the design, combined with high performance, will make it an irreplaceable assistant in the preparation of firewood for the winter.

Where to order this rack and pinion with shaft?