Content:

Frames are a necessary, one might even say irreplaceable element of every bee house, without which it will be very problematic for insects to build honeycombs.

It is impossible to know everything about the bee framework, but the main aspects must be taken into account, because the honey harvest depends on the systematically arranged hives, on the comfort and convenience of bees. In the manufacture of frames, the main thing to consider:

- rails parameters,

- used material,

- the shape of the planks,

- the number of frames in the hive.

The frames serve on average up to 10 years, gradually loosening, twisting and losing the required wire tension.

Size standards

The correct dimensions of the bee frames will ensure ease of use (hive maintenance, replacement, honey pumping, bee productivity).

The standard sizes of frames for hives have been discussed since 1814, when P.I. Prokopovich created the first frame hive, but this idea was realized only in 1918, after the congress of beekeepers of the USSR in Kiev. Certain standards for the manufacture of frames for beehives, according to the famous beekeeper V. Yu. Shimansky, will simplify the activities of beekeepers.

At the Kiev Congress, standard frames for bees of the following sizes were determined:

- 43.5 * 30 cm, according to the Dadan-Blatt type, the upper bar is 1.5 cm protruding from both sides;

- 43.5 * 23 cm, Langstroth-Root type, the upper bar protrudes 1 cm from both sides;

- 43.5 * 14.5 cm - store frame for the accumulation of honey (store - an area for collecting ready-made honey);

- 43.5 * 30 cm - Ukrainian frame, according to the first type, only inverted;

- 28.5 * 44.8 cm - Modified Dadana;

- 33 * 25 - Kuncha.

In Germany, peculiar hives prevail - 37 * 23.3 cm. Such structures are distinguished by ease of use, practically have no technical flaws and have a more civilized appearance. In domestic beekeeping, these frames have to be adjusted to the honey extractor and foundation.

These sizes of standard frames for beehives are still relevant today, they are used to manufacture equipment in both a handicraft and an industrial way.

Beekeepers have the opportunity to use frames for beehives of different design, to pull the wire in their own way, to fix the foundation, but the outer dimensions of the frame will always be limited by the capabilities of the nest. In addition, the foundation is also manufactured to specific standards.

A. G. Mannapov, Doctor of Biological Sciences, who studied bees and their habitat, refuted the "ideality" of the adopted framework standards. In his opinion, they have a lot of disadvantages. Scientists have created an innovative beekeeping aid (productivity increase) frame with 3.4 cm wide side bars, which will improve ventilation in the hive and improve temperature performance.

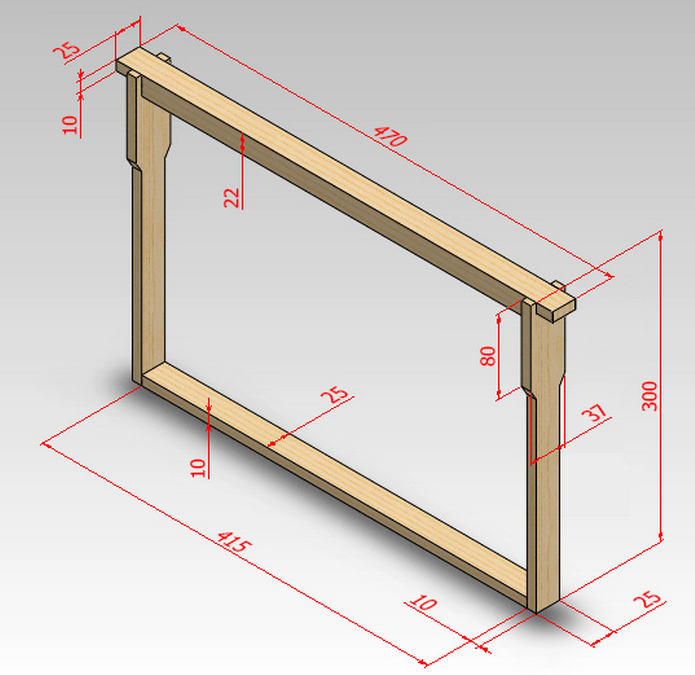

Top rail

Its length should be 47 cm, large parameters will not make it possible to stand in the grooves of the structure. The thickness can vary from 0.1 to 2.5 cm, depending on the type of hive and the personal preference of the beekeeper. The reference thickness is considered to be 1.8 cm, but many beekeepers disagree with this.

Beekeepers believe that the thinner the width of the slats, the more space is left for the bees to build their combs.By significantly reducing this indicator on all frames, you can get up to 1.5 kg of additional honey.

Side slats

The height is determined by the vertical length from the bottom to the top rail, each hive has its own. Thickness - 1 cm, a lower indicator will lead to deformation of the rail during wire tension. The common width is 2.5 cm.

Bottom rail

It does not have strict proportions, it is made from the personal wishes of the beekeeper, there are only some recommendations about the dimensions:

- width for honey frame - 1.5 cm;

- brood frame width - 1.5-2.5 cm, thickness - 0.8-1 cm.

In addition, the following indicators are taken into account:

- 37-38 mm - must be between the axes of the adjoining frames;

- 20-30 mm - is the distance of the frames from the bottom row to the bottom of the hive body;

- 5-7 mm is the distance from the walls to the side rails.

The location of the frames in the hive, the number

Frames for bees are the most important element of the hive, it is from them that the size and type of the future structure is determined. The most commonly used frame formats in beekeeping are: square, low-wide, narrow-high.

One hive can contain as many frames as you like, therefore, denoting a certain hive, they name not only the type of frames, they also mention their number in one sector.

The nest and honey frame are located horizontally, in one row - single-tier horizontal structures. If you put them in several tiers one above the other, then these will be vertical multi-tiered hives.

According to the Ruth and Dadan system, the number of frames in the hive corresponds to 10 and 12 pieces. The frames should be positioned from north to south, directed to the earth's magnetic poles. The hive entrance should be oriented to the north.

Depending on the number of rails, the hives are very diverse: 8, 12, 16, 24 frame.

Hives with 8 frames are used for young bee families that are not particularly productive or for transporting bees over short distances. 24 - the largest, intended for large families.

Wire pulling process

The wire plays the role of reinforcement when applying frames. The tension is started after the wooden frames with installed spacers are made. For this you will need:

- coil of steel wire (1.5-2 mm in diameter);

- a drill of a similar diameter, a screwdriver or drill;

- hammer;

- pliers;

- conductor or template;

- nails for fastening wire (shoe).

Step by step procedure for stringing:

- using a template drawing or a conductor, holes are drilled in opposite poles;

- a tension nail must be driven into the frame;

- pulling the wire through the drilled holes;

- the end of the wire is wrapped around the driven nail;

- using pliers, the wire is pulled and fixed to the appropriate nail.

Stand for frames with honey

A stand directly under the frames with honey is used during printing or drying by bees. During the inspection, the beekeeper needs to get at least one frame so that it is convenient to operate the rest in the hive. In order not to have to put the frame on the ground just like that, you can assemble your own stand or buy a specially made one.

Making a stand for frames with honey begins with measuring the frames themselves, since a smaller stand is definitely not useful. The first step is to make a base: you can take a ready-made baking sheet, suitable in size, a trough, a tray, you can carve it out of wood, but it is extremely laborious and not everyone can do. Next, you need two supports, for the first frame and dividers for the subsequent ones. Supports are made of thick wire, boards.

Plastic frames

The most relevant and tested over the years to harvest frames is to use wood.But constantly evolving modern technologies lead to the emergence of new, equally suitable products. Plastic is an excellent substitute for wood. It enables the manufacture of lighter, yet very durable and comfortable frames for hives.

Plastic frames for collecting honeycomb are already being produced on an industrial scale, sold in a ready-to-use design. All you need to do is cover the plastic with a thin layer of wax and install the frame in the hive. In addition to standard plastic elements, mini-frames are made to combine them into a cassette unit.

Correctly produced frames will not only make the life of bees comfortable, but also greatly facilitate the work of the beekeeper. Therefore, they approach the manufacture wisely, take into account all the nuances.