Content:

Tillage plays an important role in the cultivation of agricultural plants. The most effective cultivation method is considered to be non-moldboard cultivation. In this case, soil moisture is preserved to the greatest extent, preventing wind erosion of the soil. If a cultivator for a tractor is used as an attachment, it can be effectively used on fields with a large area.

Popular cultivators on a tractor

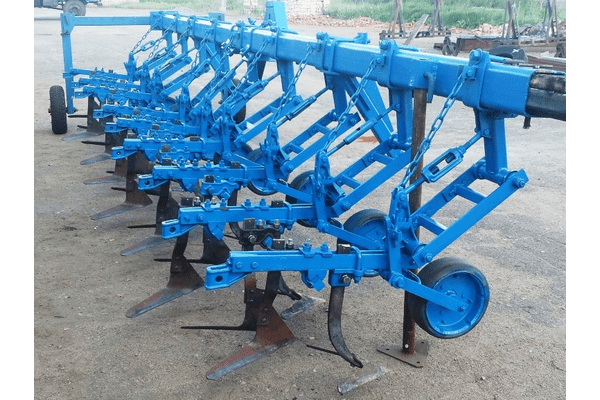

If any of these devices (cultivators Stepnyak, Leader, Polaris, Kompaktomat, Neva) are considered from the point of view of their design, then we are talking about a single-frame or multi-frame structure, including wheels for the cultivator, to which the working bodies of the device, called paws, are attached. In some cases, they can be spring loaded. The latter can be designed to perform various functions. As a working tool, for example, a harrow, plow, ripper, seeder, milling cutter or something else can be used.

By the features of aggregation

Cultivators for continuous tillage must be connected to the tractor to perform the work. This can be done in one of two ways:

- When using the mounted version, a three-point mount is used for this purpose.

- When trailed, a universal hitch is used.

Depending on the destination

Using mounted cultivators KBM, Kompaktomat, Lemken, Salford, KVF, KLZ, KMZ and others occurs with different purposes:

- For this purpose, steam devices are used, for example, the Leader wheeled cultivator. An important part of the work is to carry out pre-sowing preparation of the land.

- A row cultivator is needed for another application. It is used to care for crops. At the same time, with its help, the following combined processing is carried out: the earth is scooped up, weeds are destroyed, weeds are destroyed, the soil is loosened.

- Special mechanisms stand out. These, in particular, include cultivators at MTZ, for use in growing melons and gourds, cultivators that are designed for gardening and some others.

By the principle of work

It is customary to divide the types of cultivators according to the nature of the used draft force. There are two options:

- Sometimes the tractor, using a special drive, transfers the draft force to the mechanism attached to it.

- The suspended equipment does not have its own draft force and moves because it is pulled by the tractor motor.

Cultivators on a tractor

Cultivators are one of the most demanded types of attachments. Suffice it to recall the cultivators KSHU, Smaragd, John Deere, KLB. They have many different uses. With the help of such a hitch, you can loosen the soil, crush large clods of earth.

The Polaris cultivator can perform not only loosening of the soil, but also much more. In particular, he is able to carry out work on leveling the soil. The use of the KSK cultivator by the number of operations performed can be considered universal. It is also possible with its help to level the ground, compact the ground and do other types of work.

The main types of cultivators used as hanging equipment:

- Disk devices. Here, the working part is vertical sharp discs that cut through the soil when moving. They loosens the earth, making it more water-absorbing, contributing to its aeration. This is much more efficient than manual handling with a pitchfork.

- There are continuous cultivators using pointed knives. They are installed in such a way that during processing they rip up the turf soil without affecting the deeper layers. Such careful processing on black soil does not mix the fertile soil layer. These devices are called lancet mechanisms.

- Plowshare cultivators include a plow in their design, but they do not perform conventional plowing. In this case, the ploughshare does not wrap the soil during operation. Distinctive features of such devices are wide coverage and the ability to connect to low-power tractors.

- Soil processing, which is carried out by a milling cultivator, is carried out to a depth of 35 cm. As a result of milling, weeds cut into pieces are intensively mixed with the soil.

- Chisel mechanisms carry out ploughshare soil processing. In this case, several cutting tools are used in one device. During processing, such a wide-grip chisel does not perform soil wrapping.

- Forestry trailed cultivators are capable of cultivating the soil, the surface layer of which consists of packed dry leaves and old grass.

- Discrete Micro Raising Cultivators are designed to work in areas where the terrain is uneven. Despite the unevenness of the soil, this type of device provides full processing.

Popular models

There are a number of models that are very popular:

- The KPS-4 model is a steam cultivator used by tractors of class 1.4. Designed to move at a speed of 12 km per hour. It can be used on an area of up to 4.5 hectares.

- The cultivator KRN-5,6 is an inter-row device. Suitable for work with tractors of class 1, 4 or 2. The cultivator is adapted to work with long-stemmed crops, as well as with essential oil crops.

- KPM-8 - designed for pre-sowing processing. Works at high speed: in one hour it can process a field occupying 10 hectares.

- KRG-3,6 is a device with lancet paws, which is hydraulic. It is usually used in areas that have a small area.

- KOH-2.8. This cultivator model has a hilling function. It can be used when planting potatoes. At the same time, he can additionally perform fertilizing with fertilizers.

Other models are widely known, for example: Will Rich, KNK, Salford, KPSh, Champion, Cayman.

T25 cultivator with own hands

The purchase of a cultivator allows you to work the land efficiently. However, for large areas or for dense clay soils, it will be more effective to use this mechanism as an attachment for a tractor.

It should be borne in mind that the equipment made for one model, for example, for the KPI cultivator, may not be suitable for another (for the Ob cultivator).

Self-production of a cultivator for suspension on a tractor will require less financial investment compared to using a purchased mechanism. However, in order to make a cultivator yourself, you need to spend a lot of work.

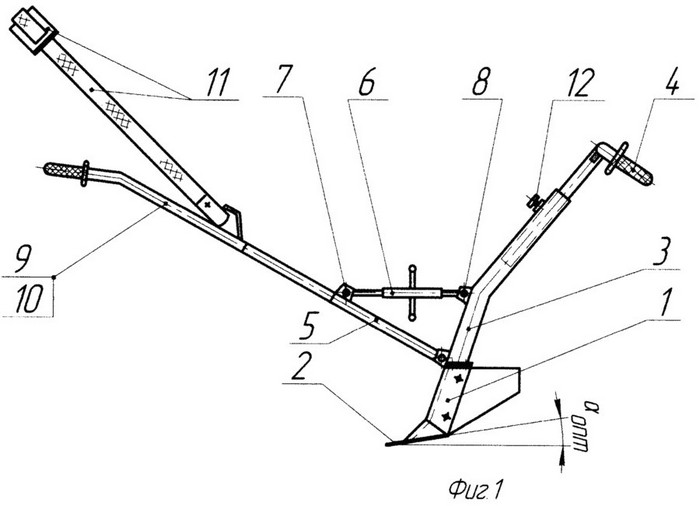

Next, we will consider the creation of a suspension device for the T-25 tractor.

Plow

It is one of the main agricultural tools for preparing land for sowing. You can make it yourself or buy a suspended plow for this tractor.

On the other hand, making a suspended plow in-house is not very difficult.

This will require a sheet of metal. It will need to be bent in a suitable way.

When making a plow, it will be necessary to take into account that in the process of work it will need to withstand sufficiently large loads. In order to provide the desired strength, a sheet of alloy steel is used for manufacturing, the thickness of which is 3-5 mm.

For manufacturing, you will need to use a metal pipe, the diameter of which is approximately 55-60 cm. Its thickness should be 4 mm.

To speed up the manufacturing process, you need rollers to bend the steel plate for the plow. Once the sheet has been shaped, finer processing can be done with a hammer.

There is a method of making a plow that does not use drums. In order to make a dump, the workpiece for it must be warmed up in a forge. To cut a metal part as needed, it is convenient to use templates made from cardboard. They can be made on the basis of the existing old blade from the T-25 tractor. The template is outlined with chalk on the steel surface of the pipe, which must first be cleaned with emery.

In order to cut the necessary parts, a gas welding machine is used. It is also used to hold the share and blade together. In order for the manufactured plow to keep the furrow, a wheeled unit is made for it. The wheel diameter must not be less than 20 cm.

It is important that the ploughshare is made removable - this will allow you to remove it and make a high-quality sharpening. When plowing, when the plow is submerged to a depth of 20-25 cm, it will be under significant load, which is why it will quickly become blunt.

Assembly technology

After the share and blade have been made, you need to start assembling the plow. They must be connected and welded to each other and to the side shield.

The plow is attached to a wheeled unit. It must have a furrow wheel, which is designed to guide the plow correctly. Its width should be 4-5 cm, diameter 32 cm. During operation, when viewed from behind, the wheel is usually located on the left side.

Plow setting

Typically the plowing depth is between 20 and 24 cm. The distance between the wheel and the share should be approximately the same. If a height adjustment is provided for this wheel in the drawing, this will allow you to control the depth of immersion of the plow.

The use of cultivators Lemken, KRN and others allows you to prepare the soil for sowing, fight weeds, huddle the beds, loosen the land and perform many other types of work. Using these mechanisms as suspension equipment allows you to combine the speed and power of the tractor with the high quality and variety of work that can be carried out using cultivators.