Content:

A do-it-yourself potato planter for a walk-behind tractor is a convenient unit used by summer residents and gardeners.

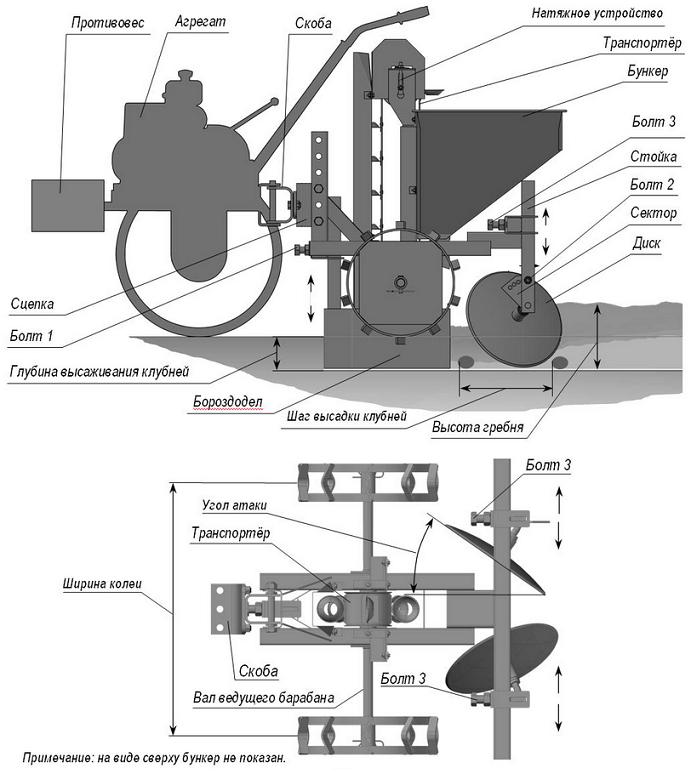

This unit consists of the following components:

- Frame with metal wheels equipped with lugs;

- Bunker for planting material;

- Chain with cups (conveyor) - mounted on 2 sprockets, one of which is fixed on the axle of the wheels, and the second - in the upper part of the hopper;

- Seed pipe - serves to move a chain with cups and tubers placed in them from the bunker to the moment of planting in the soil;

- Opener (furrower) - cutting into the soil to a certain depth, forms a groove into which tubers are placed;

- Scrapers - discs or dumps placed behind the frame that fill the groove with the tubers placed in it, forming a triangular ridge

Made independently, it has a number of advantages and several disadvantages.

The advantages of this unit include:

- Convenience and speed of planting - the potato planter allows you to plant much faster and without significant efforts on areas that are large enough on the scale of a summer cottage or farm;

- Minimization of soil cultivation - this unit allows you not to use a cultivator, hiller or harrow again. During planting, he loosens himself, makes a furrow, plants tubers in it and "closes" them from above with a sufficiently thick layer of soil;

- The same depth - a properly tuned home-made unit will plant tubers at the same depth, which will further ensure more friendly and healthy seedlings;

- Compliance with the distance between the planted tubers;

- Ease of use - planting with such a unit does not require special knowledge and skills.

Minuses:

- The obligatory presence of powerful enough equipment - in order to use both a home-made and a factory potato planter, you need a walk-behind tractor or

A motor-cultivator with a capacity of at least 5-6 hp;

- Presence of skills of a welder - to assemble the frame, a minimum skill is required to use a welding machine;

- Difficulty to Use on Heavy Soils - Compared to more powerful and sturdy implements found on larger tractors, small potato planters are less effective in heavy clay soils.

How to make a potato planter for a walk-behind tractor

A potato planter for a walk-behind tractor is a unit that can not only be purchased, but also made by hand. To do this, you need to prepare all the necessary materials and tools,

Materials

- Corner or channel for the frame;

- Support metal wheels;

- Bearings;

- Sheet steel for the rear wall of the bunker, 1.5-2.0 mm thick;

- Galvanized sheet;

- Sprockets 19-21 teeth;

- Timing chain;

- Axle for drive wheels;

- Steel wire 3-4 mm thick.

Tools

In order to make a potato planter for a walk-behind tractor with your own hands, you will need tools such as:

- Bulgarian (angle grinder);

- Welding machine (semi-automatic);

- Drill or powerful screwdriver;

- Compressor with spray gun.

Manufacturing process

- A rectangular frame is welded from a channel or corner, its size is selected taking into account the size and capacity of the hopper;

- The first sprocket is attached to the center of the axle of the support wheels;

- On both sides of the sprocket, bearings in cages of a thick-walled pipe of a suitable inner diameter are pressed onto the axle of the support wheels;

- Metal support wheels are attached to the axle;

The axle is welded to the frame; for this, the bearing cages are welded by contact welding to the transverse corner specially provided for this part of the frame.

- A spiral of 12-15 turns is wound from a wire using a vice and a pipe with a diameter of 50-60 mm;

- The spiral is cut lengthwise, making 12-15 separate rings;

- The rings are welded to the chain at a distance of 8-10 cm from each other. In order to prevent small potatoes from slipping through the ring, a bottom of the same wire or pieces of sheet steel is welded to it from below;

- For the vas deferens, a pipe with an inner diameter 10-55 mm larger than the diameter of the cups (metal rings with ends for tubers) and with a length equal to about half that of the chain is used. A longitudinal cut is made in the pipe, 20-30 mm wide;

- The seed tube is welded to the frame using two thick-walled metal plates;

- In the upper part of the seed tube, the cut is increased to a width of 40-50 mm;

- The chain is disconnected with the help of the lock on it and put on the lower, and then on the second sprocket. At the same time, it is carefully passed through the seed tube;

- The upper sprocket with an axle and two bearings is welded to the seed tube with the help of corners;

- In parallel to the seed tube near the lower sprocket, a pipe is welded to the frame, inside which a chain with cups is inserted;

- The rear wall of the bunker is welded to the pipe and to the ends of the corners on which the upper sprocket is attached;

- A bunker with a capacity of 20-30 kg is riveted or welded from tin, 0.8-1.0 mm thick;

- In the upper part of the seed tube, two limiters are welded parallel to the movement of the chain, which are necessary so that the potatoes, falling out of the cup when turning over, fall into the pipe, and not past it;

- Covers are welded to the rear of the frame; for this, two convex plates are welded to the racks. Place the harvesters at an angle so that they, covering the furrow with the planted potatoes with earth, form a ridge above it, 40-50 mm high;

- A trailing attachment for attaching the unit to the walk-behind tractor is welded to the front of the frame (it can be used to adjust the height of the attachment of the potato planter to the walk-behind tractor), as well as the opener. The body of a conventional hiller is used as an opener. The center axis of the opener should be located under the center of the tube from which the cupped chain exits;

- On the wheel rims, lugs are welded in a checkerboard pattern - plates 20-30 mm high, located on the rim with a pitch of 40-60 mm;

- The frame, hopper, support wheels are cleaned, degreased and covered with 2-3 layers of paint.

The approximate dimensions of a potato planter manufactured according to the technology described above are as follows:

- Frame - 580 × 300 mm;

- Drive wheel diameter - 310 mm;

- The distance between the wheels (track) - 585-600 mm;

- The length of the seed tube is 770 mm;

- The distance between the axes of the sprockets is 570 mm;

- Hopper (length × width × depth) - 370 × 400 × 400 mm;

- Zagotachi (length × height) - 275 × 140 mm;

- Top sprocket - 19 teeth, bottom - 21 teeth;

- Bearings - 4 standard 205 size bearings.

TOP-3 factory models of potato planters

Among the factory models of potato planters for a walk-behind tractor, the following are the most popular:

- KS-1;

- KS-1A;

- KSM-1.

KS-1

- Type - single row, trailed;

- Weight -25 kg;

- Track - 700 mm;

- Hopper capacity - 40 l;

- Productivity - 0.15-0.2 g / hour;

- The required power of the walk-behind tractor is from 6 hp;

- Price - 12000-14500 rubles.

KS-1A

- Type - single row, trailed;

- Weight -33 kg;

- Track - 600 mm;

- Hopper capacity - 34 l;

- Productivity - 0.25 g / hour;

- The required power of the walk-behind tractor is from 6 hp;

- Price - 15,000-16,000 rubles.

KSM-1

- Type - single row, trailed;

- Weight - 44 kg;

- Track - 600 mm;

- Hopper capacity - 41 l;

- Productivity - 0.25 g / hour;

- The required power of the walk-behind tractor is from 6 hp;

- Price - 15500-16000 rubles.

All these models work well with motoblocks, both domestic (MTZ, Neva, Salyut) and foreign production (Viking, CAIMAN, Daewoo).

Thus, a home-made inexpensive potato planter for a walk-behind tractor is a very convenient, easy-to-use, but at the same time, a unit that greatly facilitates the work of a summer resident or a small farmer. Such a homemade product made from materials available to everyone, in comparison with store counterparts, will have a cost several times lower, without yielding to them in quality and reliability.