The vibrating-screening potato digger (or shaker) is designed to improve the process of collecting vegetables using a walk-behind tractor. Suitable for picking various vegetables. A roaring potato digger for a walk-behind tractor simplifies the work of farmers, speeds up harvesting, and reduces the cost of producing agricultural products.

Description

The peculiarity of the potato digger of the "Salute" type and others is that a knife is mounted to it to a frame driven by a walk-behind tractor. It allows you to harvest on all types of soil, even heavy ones. This digger cleans tubers well and increases labor productivity.

The mass of the units ranges from 30 to 50 kg. They allow the teeth to be inserted into the ground to a depth of about 20 cm. The working width of the potato diggers is 32-37 cm, which significantly speeds up the harvesting process.

This machine is structurally similar to the conveyor one. Its difference is that there is no conveyor in it. It can dig out tubers in each row, which is very convenient if potatoes of various varieties are planted in the field.

Benefits

Of the advantages of the operation of this unit, farmers note the fact that it greatly facilitates the work of a person during harvesting. It is used not only for collecting potatoes, but also for other vegetables: carrots, beets. The device saves time and energy. The potato digger, the Patriot walk-behind tractor, provides excellent harvesting results.

Before purchasing a potato digger, you should make sure that it can be installed on a walk-behind tractor and a motor-cultivator.

Principle of operation

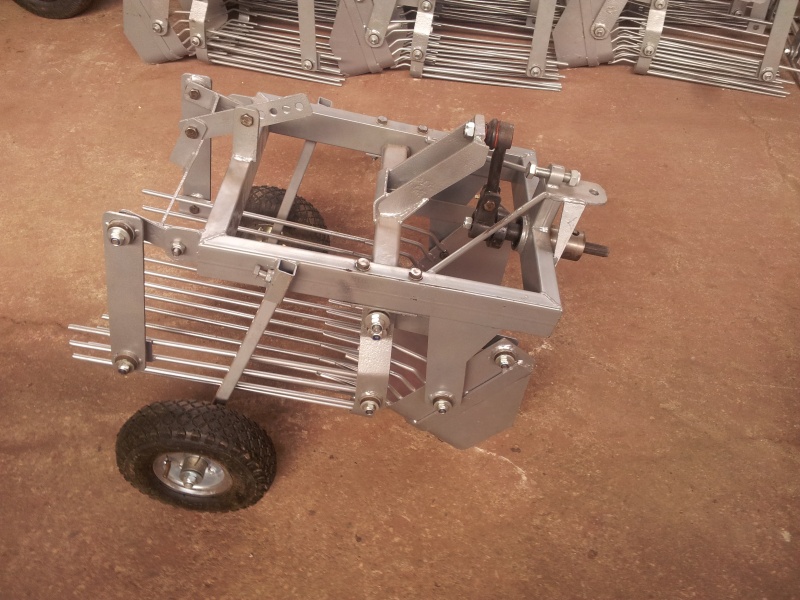

The device of the screening potato digger for the Neva block and other units is a carriage located on two small wheels. Its body is a body welded from steel wire. The distance between the twigs is from 20 to 30 cm. This is necessary so that the potatoes are cleaned of tops and soil impurities.

A shovel is installed in front of the carriage. It is made of sheet steel, the rods are welded from behind, bending them slightly downward. This is necessary so that the shovel is fixed at the front of the body. The shovel is mounted so that in the lower part it is located a few centimeters below the body of the potato digger.

When you reciprocate back to the body, the shovel lifts up and throws the dug potatoes into the wire body for cleaning.

The principle of operation of the potato digger is based on the fact that reciprocating movements are transmitted to the shovel with the help of a lever and a connecting rod from the power take-off shaft. The rotary movement through the digger mechanism is transmitted using a chain drive or a shaft extension to the potato digger, turns into a reciprocating motion, drives the shovel. She goes down, blasting potatoes. Moving the walk-behind tractor forward moves the dug out vegetable into the body.

Manufacturers

These devices are manufactured at many enterprises in Russia and the CIS countries. Below is a list of the most famous enterprises producing potato diggers:

- The Agromotoservice plant, located in Starokonstantinov (Ukraine), produces the potato digger KM-1P. This device is recognized as one of the best on the Russian and CIS market. It is certified according to all the requirements of the ISO 9001: 2009 standard.

- IE Akimov (Cheboksary, Russia) produces a potato digger KKM-2. It is widely used by Russian farms.

- LLC "Mechanical Plant", located in Molodechno, Belarus, produces high-quality and reliable potato digger KM and its version KM-2.

- SAZ LLC (Smorgon, Belarus) produces a digger KFT-2. This is a powerful and reliable digger, works on the basis of the Belarus walk-behind tractor.

- LLC "Beltraktora" (Brest, Belarus) manufactures potato digger KT-5. Its designers are constantly working to improve the model and improve its performance.

Operation and care

When driving for the first time, it is necessary to carefully adjust the immersion depth of the knife and the rotation speed of the unit. It is necessary to immerse the knife to such a depth that it does not damage the tubers or leave them in the ground. The blade depth is adjusted using the support wheels and the hitch assembly.

With proper operation with a digger, a small amount of soil and tubers remain at the exit.

If the tops have grown strongly, you need to remove them from the field a day or two before harvesting.

The digger is assembled in the following sequence:

- attach a digger to the hitch unit, tighten the bolts for fastening;

- check the strength of all connections;

- install a large digger pulley;

- install a tensioner;

- fasten the drive belt to the pulley of the walk-behind tractor and potato digger through the tensioner;

- make sure the tensioner is working;

- check for grease in the joints.

Getting started, you need to fulfill the following safety requirements:

- make sure that the digger is on level ground;

- do not sit in the tractor and do not sit on the digger during work;

- do not lubricate parts and do not clean the machine during operation;

- carry out any work only after the complete stop of the unit;

- make sure there are no hanging ends in the clothing.

This unit needs proper care. After work, all parts must be thoroughly cleaned of soil residues. It is strictly forbidden to allow moisture to remain on the parts.

The unit must be kept dry. All moving parts should be periodically lubricated with machine oil. The walk-behind tractor must be in a stable position.

DIY potato digger

In order to make a potato digger with your own hands, you will need the following materials and tools:

- metal frame (it is made by welding several corners measuring 63x40 mm to each other).

- iron channel, pipes with a diameter of 13 cm;

- sheet metal (its thickness must be at least 7 mm);

- fittings with a diameter of 10 mm;

- hardware;

- chain (used to transmit rotational movements);

- metal racks (they are made from pieces of pipe, channel);

- metal or rubber wheels;

- metal or reinforcing drum;

- bolts No. 10.

To make a digger, you will need the following tools:

- welding machine (for connecting parts and building an iron frame);

- wrenches;

- hammer;

- sledgehammer;

- scissors for metal;

- saw for metal;

- drill and drills.

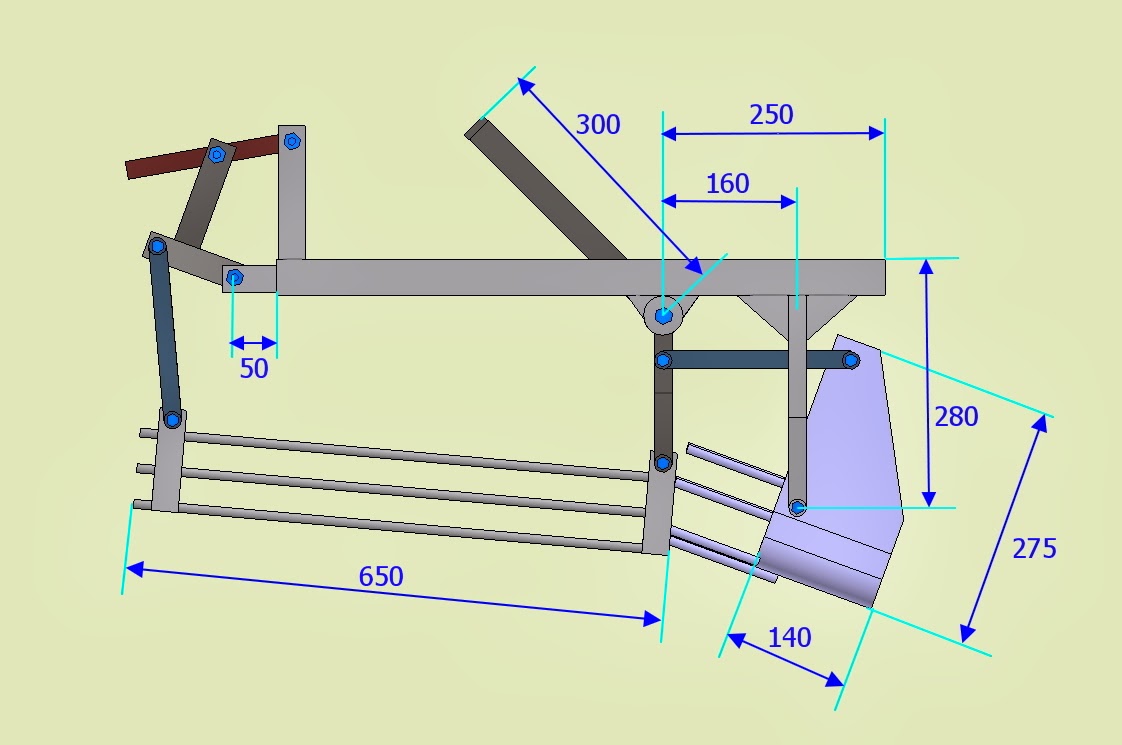

When working, you should adhere to the drawing of a roaring potato digger for a walk-behind tractor. The sequence of actions when assembling this unit is as follows:

- Manufacturing a frame using a welding machine from corners and a channel. The entire structure will be held on it. Its length should be approximately 120 cm.

- Having stepped back 30 cm from the frame, weld the channel for installing the regulating parts.

- Connect the posts by welding.First, you need to install the longest stand 50 cm, then two more - 40 and 30 cm each. The base is welded to them.

- Connect the struts with the remaining parts of the channel. After correct work, they should have a triangular shape.

- Weld a sheet plate about 30 cm wide to one of the triangles.After the whole structure has cooled, bend it with a sledgehammer, fix it near the second triangle. The ploughshare is made from machined metal plates and is attached with bolts.

- Weld the reinforcement to the base. A thick sheet of metal should be placed on the sides of the metal rods.

Then the shafts are installed on the elevator, reacting to the rotation of the wheel mechanism. To assemble the support-transport unit, you need to fix the rod using sprockets. It is necessary to weld the disks to which the wheels are attached.