Content:

A potato digger for a walk-behind tractor is a special attachment for mechanization of the last cycle of potato growing - digging. It greatly facilitates the work of the landowner. The harvest is dug up within a few minutes, depending on the size of the plot, it remains only to collect the potatoes in bags. Devices are of different types, intended for small household farms with different soil conditions.

Types of potato diggers for motoblocks

Digger fan, lancet or dolphin

Suitable for motoblocks of any brands, including those with low power. The design has the simplest device, which is a plow with fan-shaped welded rods that perform the sifting function. Principle of operation: the walk-behind tractor pulls the digger, the plow enters the ground and digs in the potato whips, pulling the potatoes to the surface, falling on the fan grate, the earth is sifted out, and the potatoes remain on the surface of the field. This form of digger is suitable for various soils and any debris in the field from tops or weeds.

The fan-type digger also has disadvantages, so during the digging some part of the crop is damaged by cutting the potato into pieces with a plow. This is especially true for those who plant potatoes for sale. Controlling a walk-behind tractor with such attachments requires significant physical effort, and for large processing areas - increased fuel consumption. But given the low cost and the simplest and most understandable design, it is easy to buy it or make a manual potato digger yourself. This does not require schematics or mechanical and turning skills. But experience with a welding machine and metal will be needed. A shovel or a plow can be used to make a rally; all that remains is to weld the rods. This design is also good in that it has no moving parts, and the breakdown, if this happens, is easy to fix.

Vibrating or screening type potato digger

It has a more complex device containing twisting mechanisms that create vibration. It has a wider furrow coverage than a plow. Penetrates to a depth of 20 cm. High digging efficiency, due to vibration, cleans potatoes well from soil and throws them onto the surface of the field. Potatoes are removed completely, unless they are buried atypically deep in very loose soil and are not covered with earth. The cultivator goes effortlessly, digging out the potatoes very quickly. One of the conditions for good work is a clean field from haulm and weeds. Before starting work, you need to cut the potato tops.

Conveyor type

Such a potato digger can resemble a potato harvester for private farming. Also called belt or conveyor. In terms of work, it is similar to a vibrating potato digger for a walk-behind tractor, but it is improved by a conveyor belt, onto which the potatoes are fed after they are dug out by the device. The conveyor belt is made from metal rods or mesh, there are also rubber belts. The longer it is, the better the potatoes peel.It is set in motion from a shaft transmitting torque through a gearbox. The conveyor type of the digger is distinguished by the peculiarity of well peeling and separating potatoes from the ground and whip, the potatoes are not damaged. To use this model, a tractor or walk-behind tractor is used, which produces power take-off using a shaft. A do-it-yourself conveyor potato digger can be assembled if you have the knowledge and skills to work with such mechanisms. It can also be modified and improved in a private economy and facilitates gardening work.

The prices of vibrating mounted diggers are quite high, so you can think about building such a device with your own hands.

How to make a roaring potato digger yourself

When the farm has a minitractor or walk-behind tractor, for example, brands such as Neva, MTZ, Salut, made in Moscow, then attachments such as a potato digger can be made independently. The implementation of the units depends on the skills of using tools, welding, their availability and understanding of the operation of mechanisms. Some units or elements can be purchased separately, ordered to grind parts, use removable parts from other devices.

Tools that will be required:

- Bulgarian;

- drill;

- welding machine;

- level,

- roulette.

Used materials and elements:

- metallic profile;

- sheet metal;

- metal corners;

- metal rods;

- traction;

- steering tips;

- stabilizer's pole;

- pulleys of a potato digger and a walk-behind tractor of different sizes;

- drive belt;

- bolts;

- wheels;

- shafts;

- materials for hinges.

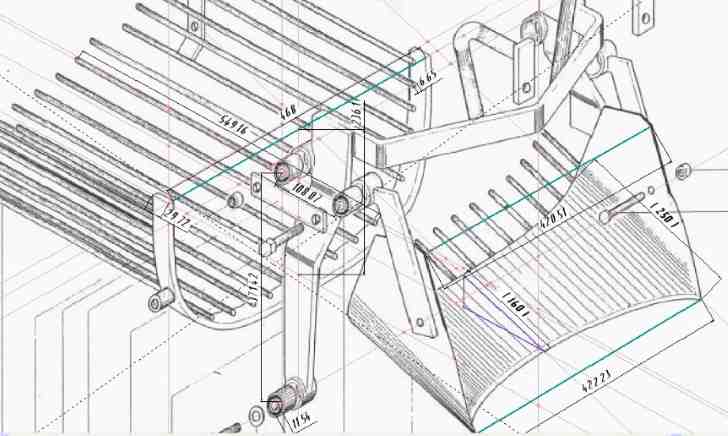

To get started, you need to draw up a drawing, taking into account the required size of the digger. A ready-made diagram or viewing devices of already existing factory designs can be used. Vibrating digger consists of: base frame, ploughshare-knife, coupling, reduction unit, poly-V-belt, shafts, support wheels.

The procedure for collecting the construction of a homemade potato digger:

- They make a welded frame: a profile pipe 40 * 40 mm or 50 * 50 mm, and possibly any that is, but not thin, cut into the desired size: two short, two long. The elements are connected by welding, creating a rectangular frame. The edges are sanded;

- Racks with wheels are welded to the back of the frame, which will hold the structure at the back. A hole is drilled in the holder for attaching the wheel struts with bolts. Racks are made, support wheels are attached to them, holes are drilled to adjust to the desired excavation depth. Wheels can be metal, rubber or lug, which will better follow the type of soil on the site;

- For the front part, a hitch is constructed that connects the potato digger with a walk-behind tractor; it can be made with a hitch adjustment, according to the model for the required model, or you can buy a ready-made one;

- Holders for hinges are welded inside the frame, in the form of a triangle on which the screen will be suspended;

- A bracket is welded to the frame to install a gearbox and a mechanism to create vibration in the device;

- A ploughshare knife is made from a metal sheet, corners are cut and bent. A high load is given to the ploughshare, therefore it is recommended to make it from durable materials, for rigidity the folds are boiled from the inside, an additional plate is applied on top. The main function of the share is to cut the ground, so that part of it that will be directed into the soil is sharpened. The ploughshare is attached to the front of the device with rubber-metal hinges;

- To the ploughshare of a potato digger, to the opposite part from the one that will sink into the ground, rods of wire or reinforcement, with a cross section of 10 mm, are welded, which will perform the function of a screen or sifter;

- The moving parts are connected: gearbox, lever, connecting rod, rods, eccentric, drive belt. The reduction unit is mounted on bearings. The torque from the motoblock shaft is transmitted through the gearbox to the lever and connecting rod, creating vibration of the plow-shaker;

- To reduce vibration, a pair of eccentrics is installed, in this case the digger works more smoothly and gently. In addition, an additional eccentric, removing vibration from the walk-behind tractor, gives more comfortable control;

- The unit is painted with paint to protect the metal.

At the beginning of operation of the screening potato digger, its design may require revision. A rumble or a rotating mechanism can be improved by a master who understands how to make a potato digger with his own hands. The grate of the purifier is constructed of various types, in the form of a vibrating table, drum or box. The frame can be square. And the knife is sometimes fixed motionless. Parts of the device can be connected not by welding, but by bolts, which, with high vibration of the device, may turn out to be more reliable fastening. A spring tensioner is installed to tension the belt. To increase the adhesion weight, you can make the walk-behind tractor body heavier by hanging a load of 50 kg or more.

Those who like to improve the productivity of work on a personal plot, to mechanize various stages of growing vegetables, use various modern techniques. A do-it-yourself potato digger for a walk-behind tractor is available to build in different versions, taking into account the existing skills and materials.