Content:

Many farmers practice poultry farming. In this difficult task, an incubator is a reliable assistant to a person. Industrial models are quite expensive, therefore, the creation of artificial hens with their own hands is widely practiced. And what exactly is an incubator? An incubator is a machine for artificial hatching of chicks of all kinds of birds.

Homemade designs have some advantage:

- minimum cash spending;

- elementary and durable structures;

- the model is made for as much incubation material as the breeder needs. In particular, it is possible to make a model with a higher capacity than a standard incubator.

What are homemade incubators

Before figuring out how to make an incubator, consider the variety of home models. Any auxiliary materials, as well as already inoperative mechanisms, are used for manufacturing.

The most popular are the following models:

- re-equipment of an old refrigerator into an incubator;

- carton boxes;

- foam sheets;

- wooden boards (plywood).

Any poultry farmer can safely choose another other material or give preference to those already listed. An important role is played by the size of the "artificial brood hen", they are calculated from the number of eggs planned to be laid.

What you need to know about sizing

It is necessary to calculate in advance the size of the homemade device, the parameters depend on the volumes that the farm is oriented towards and the number of eggs that will be laid one-time. It is the second factor that plays a decisive role.

An incubator with an average size of 450 × 300 (length and width) can accommodate approximately the following amount of incubation material:

- goose eggs - 40 pieces;

- turkey (duck) - 55 pieces;

- chicken - 70 pieces;

- quail - 200 pieces.

The size will also be influenced by the option of the heating system, the location of the lamps and the materials that will be used for manufacturing.

What should be an incubator

Starting to mount the incubator with your own hands, you need to remember the end result in order to get an apparatus in which all the nuances will be observed, allowing the chicks to hatch relatively healthy in due time.

An "artificial brood hen" is set up in such a way that all the conditions that a live hen creates for its chicks are in the hatcher. The most important role here is played by indicators of humidity and temperature conditions. When designing, it is worth considering the convenience of human use, because the farmer must control the entire process from start to finish.

On the first day of the incubation period, the material should warm up as much as possible (there are indicators for each species of bird). By the time the chicks are born, the indicator is reduced to a minimum.The exception is quail, the entire period in the incubator must be kept at a temperature of + 37.5 ° C.

Do not allow overheating or low temperatures in the machine. Overheating leads to the fact that the internal organs of the young are deformed and deformities appear. At low values, the livestock simply will not be born.

Moisture readings will vary depending on the phase of development of the embryo:

- bookmark - pecking - 50-60%;

- pecking - withdrawal - 80%;

- selection of chicks - 55 - 60%.

Incubation of eggs in different species occurs at different temperature indicators, you can get acquainted with the data in the table below.

| Bookmark | Temperature regime at the beginning of incubation | Temperature regime at the end of incubation |

|---|---|---|

| Chickens | 38 - 39 | 37.6 |

| Ducks | 37.8 | 37.1 |

| Geese | 38.4 | 37.4 |

| Turkey | 37.6 | 37.1 |

| Quail | 37.5 | 37.5 |

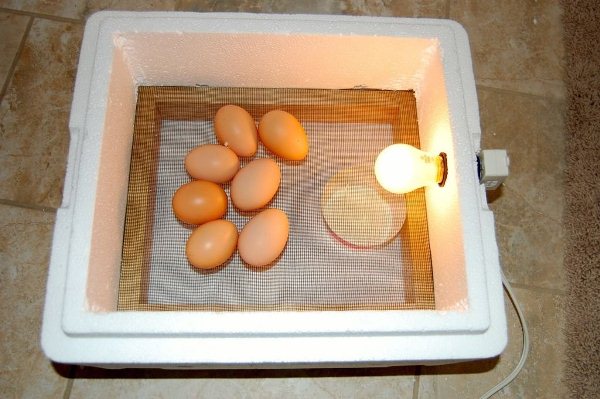

Styrofoam incubator

The foam has very good thermal insulation, and therefore it is this material that poultry farmers choose for installing an incubator. It is necessary to cut out parts of suitable size from the sheets; it will be easy to connect them with adhesive tape to obtain a cubic structure. The walls reliably keep the heat necessary for the successful development of chicks.

As an additional heating system, 20 W lamps are used. The heating elements are fixed on the inside of the lid so that there is a distance of at least 15 cm between them and the incubation material.

To make hatcher trays in a homemade incubator, you can take wooden boards or purchase a ready-made structure in a specialized store. The trays are installed in the central part of the machine so that the same distance to the heating lamps and bowls of water is maintained. The latter are set to maintain the desired moisture percentage.

It is important not to forget about observing the required distance between the walls and trays for hatching chicks. This is necessary to ensure air exchange. There is an automatic turning egg incubator, but in this model the function will be carried out manually.

To keep the temperature readings under control, the thermometer must be fixed so that the scale can be seen without opening the incubator. To maintain humidity and ventilation, several holes must be made in the top and bottom of the box.

How to turn an old refrigerator into an incubator

You should not hastily get rid of the broken refrigerator, it can be given a second life, but already as an "artificial hen". The creators of such a familiar household appliance made sure that the set temperature was maintained inside thanks to the heat-insulating walls.

Shelves with shelving can be easily converted into egg trays. The material will be laid evenly if you use the fastening grooves located along the inner walls. At the bottom, containers with water are installed to help maintain moisture. A description of everything that should be in the incubator is presented below.

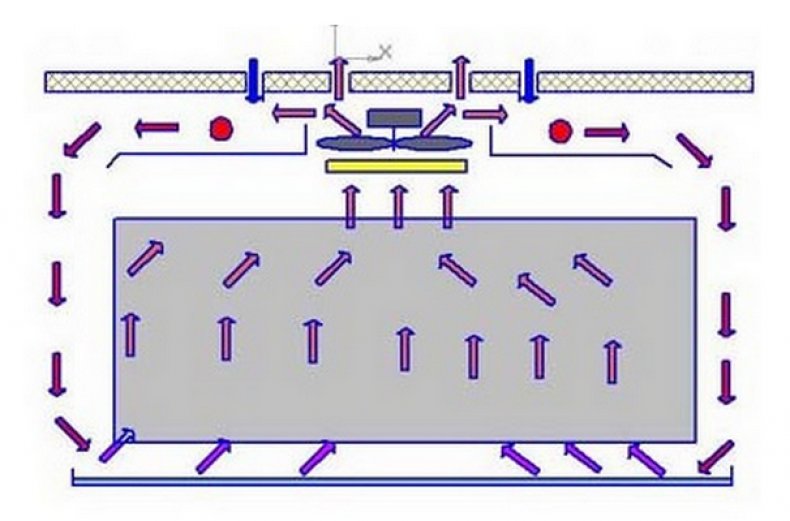

Ventilation system

Each factory model, as well as in incubators from a refrigerator, made by hand, must have ventilation. The condition of the air inside the car, as well as temperature and humidity, depend on this important system. Thanks to all these complexes, an ideal microclimate will be created, suitable for breeding chicks.

The best option is called the air speed of 5 m / s, it will be provided by a running fan. The bottom and top of the case will have to drill holes for the circulation of air masses.

Heating system

The simplest heating system consists of ordinary light bulbs.They are evenly distributed below and above the structure (of course, inside). There is only one requirement for the lower light bulbs: they should not interfere with water tanks that act as humidifiers.

The incubator thermostat will help maintain a suitable temperature. It is customary to use three types at once

- bimetallic plates;

- mercury thermometers equipped with electrodes;

- barometric sensors.

One is responsible for closing the electrical circuit as soon as the required temperature is established. Thanks to the second, heating stops. The third closes the circuit if overpressure occurs. It is most convenient to use temperature sensors to control the indicator.

How to flip eggs

In a do-it-yourself egg incubator, just like in standard models, turning the eggs is imperative. The process can be either manual or automatic, the second is more convenient.

The mechanism is very simple. Thanks to the actions of the electric motor, a motor impulse enters through the rod, which moves the trays. An egg incubator with automatic egg turning can be made by yourself:

- A gearbox is installed below.

- The assembled wooden frame will hold the trays fixed in such a way that they tilt 60 degrees towards the incubator door and the same amount in the opposite direction towards the wall.

- It is important not to forget to firmly fasten the gearbox.

- The electric motor is connected to a rod, one of the ends of which is connected to an egg tray.

Incubator from a cardboard box. Assembly instructions

Such a do-it-yourself incubator model, created at home, is the least expensive financially, and you will have to devote only a few hours to working on the model. The design has one minus - fragility due to the fragility of the main material.

- You need to find an unnecessary box of the same size as the planned incubator. The inner walls are pasted over with felt or several layers of paper.

- Holes are made through which the electrical wiring will go. On the inside, 25W bulbs are attached, between them and the egg trays should not be less than 15 cm.To prevent heat loss, all unnecessary slots (wiring passages) must be plugged with cotton or left as ventilation, but it is important not to forget to monitor the temperature ...

- Installation of wooden trays, assembly of slats (for installing trays), door manufacturing.

- The thermometer will help determine the temperature in the incubator. To maintain the desired level of humidity, containers with water are placed at the bottom of the box. It is recommended to make a small viewing window in the upper wall to control all processes taking place in the incubator.

Making an incubator for personal use is not as difficult as it sounds. A homemade car will be a great help on a home farm. Difficulties with the acquisition of the necessary materials should not arise, and their cost will be a pleasant surprise for any poultry breeder.