Content:

When the time comes to dig up potatoes, summer residents can do this in the usual way - with a shovel. However, such work is very time consuming. For its implementation, it is beneficial to use mechanization means. One of them is a roaring potato digger. The article will talk about what it is, and how you can do it yourself.

The principle of operation of the screen type potato digger

In order to dig out potatoes, a horizontally located ploughshare is used. He cuts the soil at a certain depth and digs out potatoes, which are mixed with stones and earth.

After that, everything falls on a horizontal grid, which vibrates strongly. This shakes the ground, and roots and stones slowly move back and then fall to the ground. Such a grid actually plays the role of a conveyor.

The diving depth is adjusted by setting the height of the potato digger in relation to its wheels. It also provides the ability to adjust the strength and frequency of vibration.

The rattling potato digger can also be used to harvest other root crops such as carrots, garlic, or others.

A potato digger for a walk-behind tractor without a rumble with your own hands can be made with less effort, but in terms of the quality of work it is inferior to a rumble one. Instead of a horizontal share, she uses one that resembles a shovel blade, to which metal bars extending back and up are welded.

There is also another design option - a homemade conveyor potato digger. It is sometimes called a conveyor belt.

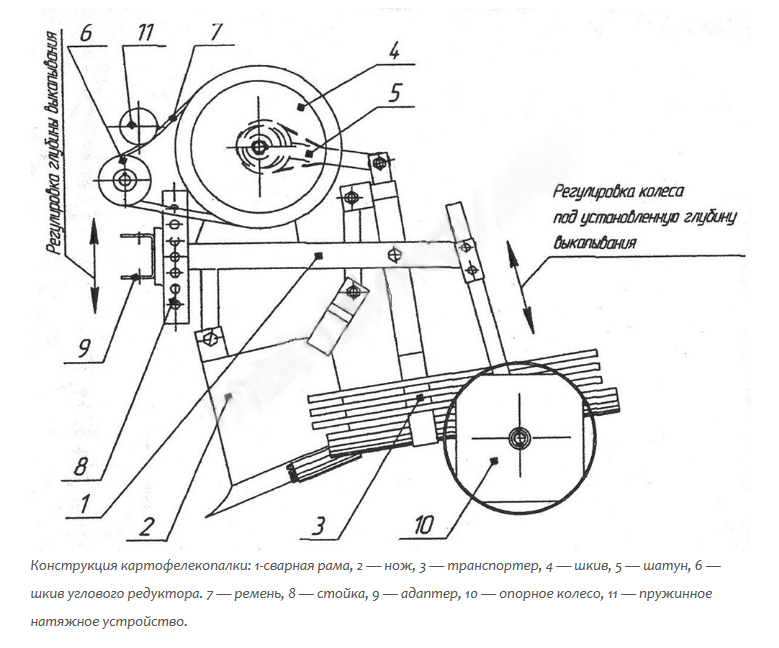

Description of the screen type potato digger

This mechanism is an attachment for a walk-behind tractor. You can work with this model of a potato digger alone or together.

In the latter case, one worker operates the walk-behind tractor, the other follows and collects the potatoes in a container.

When passing the bed, the roaring potato digger cuts the soil layer with a ploughshare, which moves on the rods as it moves. The latter are placed at such a distance from each other that the potatoes cannot fall out through them. As the grate vibrates, clods of earth are crushed and spilled through the bars. Potatoes and rather large stones remain on it. Due to vibration, they gradually move back and fall out of the potato digger to the ground. This is similar to how the transporter is used. After that, they will need to be collected in a bucket. Such work is similar to work on a conveyor belt.

Advantages and disadvantages

The positive aspects of using a screening potato digger are:

- The procedure for digging up potatoes is greatly facilitated.

- The ability to make a roaring potato digger with your own hands.

- Simplicity of the device and ease of use.

- The device can be double-row.

However, the potato digger has its drawbacks:

- It is difficult to use on large farms.

- If the soil is dense, then the use of such household units will be ineffective.

How to make a potato digger with your own hands

This home appliance can save a lot of time and labor when digging out potatoes.It should be borne in mind that it is possible to make a roaring potato digger with your own hands. The following will describe how this can be done.

To work in a summer cottage, there is no need to make a large unit. In this situation, it is more advantageous if it is small in size.

A do-it-yourself potato digger for a mini-tractor of a screening type is done as follows.

In order to start making a mechanism, you need to prepare in advance:

- metal channel;

- a ploughshare (also called an opener), with the help of which the roots are directly dug up;

- a metal plate is required with which it will be necessary to connect the opener to the grid;

- iron corners measuring 63 x 40 mm;

- several iron rods are needed (usually 8 pieces are used for this purpose)

The basis for the design is a homemade frame. It consists of the following parts:

- The base that serves as the basis for the potato digger.

- Wheels.

- Vertical rods with mounts. They are needed in order to regulate the depth of immersion of the share.

- Suspension - it includes the nodes below the frame.

For manufacturing you need tools:

- welding machine;

- drill;

- Bulgarian.

Work progress

The frame must be made of a pipe that has a square cross section. Its dimensions are: length - 4 m, section - 40 x 40 mm.

From this piece of pipe, having cut it with a grinder, you need to get four parts:

- two 120 cm long;

- two more with a length of 80 cm.

After that, you need to weld these pieces so that you get a rectangle 120 x 80 cm.

Transverse parts are welded to the frame:

- The first pair of them at a distance of a quarter of the length from the rear edge - the planks are directed downward. A metal strip will be welded to them, which will become the base on which the rods should be held.

- In the middle part of the frame, a horizontal section of the pipe is welded. A structure will be attached to it, which will be used to create vibration. Also, a narrow metal strip is attached to them, on which metal rods will be mounted.

- At the back of the very edge on the outside, you need to vertically install pieces of square pipe with a section of 40 x 40 mm. Here it is required to make holes with a welding machine in order to fix the vertical stands for the wheels with a bolt.

Now you need to install the wheels. They must have an axle that is fitted with square uprights (30 x 30 mm) that are welded to it. They can be set to the desired height, which will allow you to adjust the depth of the ploughshare.

Wheels:

- They can be metallic. They will make the structure heavier and improve the quality of its work.

- Sometimes simple rubber wheels are installed. They are not suitable for all types of soil.

- If you take rubber tractor wheels, they will be heavy and can be used for working on loose or wet soil.

The ploughshare is made from a wide metal strip bent in the shape of the letter "P". Holes are drilled in its wings, the same must be done in the slats. Screws are placed in them and then screwed tightly. To ensure strength, you can use not one vertical bar, but two made by a triangle.

The rods are welded to the iron strip, which is the base for them, and to the edge of the share.

The vibration mechanism is based on the operation of the motor-block motor, which is connected by a pulley to a wheel on a potato digger located above the frame. During its operation, the transfer pulley rotates a small wheel, on the edge of which, perpendicular to it, a horizontal metal pin is welded. It is rigidly attached to the cross bar, which is located in the middle of the frame. Rotation creates small, frequent movements up and down.The vibration can be controlled by adjusting the motor speed.

For attachment to the walk-behind tractor, a corresponding adapter is welded in front.

The roaring potato digger, due to the low cost of manufacture and ease of use, makes it possible to harvest potatoes with significantly less time and labor, compared to the conventional method, when a shovel is used for this purpose.