Content:

Various technical devices provide invaluable assistance to farmers in the preparation of feed. Among them, a mechanized rake for a tractor or minitractor stands out. Such a mechanism is desirable for every responsible host farmer.

Description of tractor rakes

Tractor rakes are designed for raking in shafts and then turning over meadow grasses and hay mowed during harvest, as well as for collecting straw after harvesting grain. These operations ensure the yield of a quality feed product, the duration of their storage and protection from the winds.

This unit consists of:

- several sections - a rake with curved spring teeth, which are interconnected by a system of hinges and are located at an angle of 45 degrees in the direction of travel;

- lifting mechanism, it moves hay / grass forward and to the side, forming a loose swath;

- support wheels.

After that, the working unit (teeth) come to their original state. In areas of a small area, the main work is done by the middle section, the side ones are used for swaths.

Any kind of rake of this type, as the name suggests, can only be operated with tractors, mini-tractors or monoblocks - they do not have their own course. The rake is mounted on the frame, where there is a spoke with a trailer, with which the rake is attached to the tractor. The rake bar can be raised or lowered using a hydraulic cylinder, depending on the desired size of the hay rolls.

The tedder rake is equipped with a floating suspension, which perfectly absorbs when hitting different uneven ground. The wheels of the units are interchangeable and are mounted on a pair of bearings, which makes maintenance and maintenance easier.

How different models work

The main working element of all types of tractor rakes is the teeth, which are melted from high quality steel, so they are not afraid of falling stones or other debris.

By design nuances, tractor rakes are divided into three subgroups:

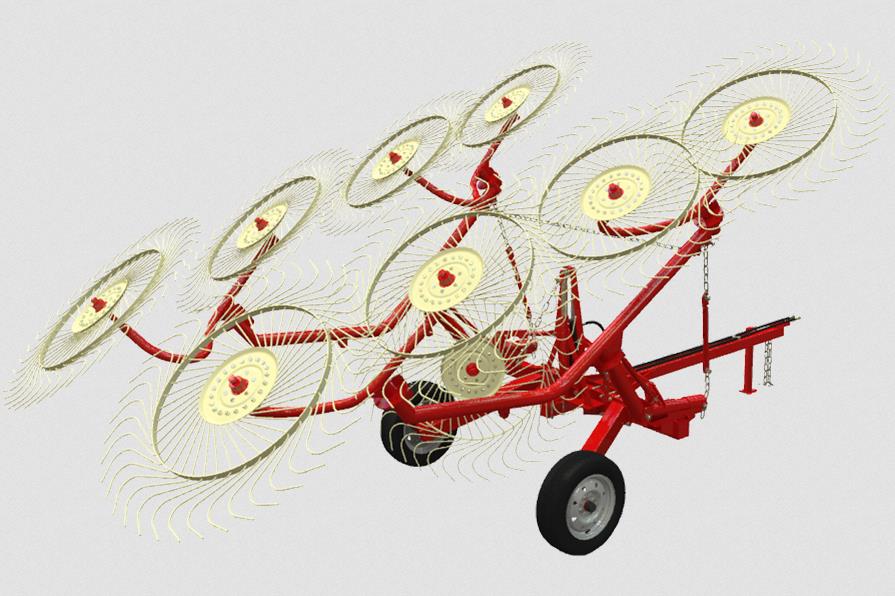

- rotary (rotary) ones are designed from replaceable raking elements mounted on the right and left rotors, while some of them perform raking and turning functions, the second - turn and scatter the resulting rolls; rotors can work in pairs or one at a time, these are one of the most expensive models of this type of agricultural machinery;

- wheel-finger rakes have as a working mechanism - rotating discs with inclined (45 degrees) spring "fingers" (spokes),which grab hay while moving the rake; the number of spokes on the rake tedders for tractors and mini tractors is 4 dozen; the movement of the wheels is carried out due to the adhesion of the apparatus to the surface of the field; very productive due to a well-thought-out design, however, they can only roll dry grass;

- the simplest design of a tractor transverse rake - they are not intended for tedding, they only rake the raw material into rolls that are formed across the tractor stroke; the wider the cultivated area and the more powerful the tractor, the better the tractor transverse rake works; sections and teeth are hinged.

Model overview

For a better understanding of the principle of operation of a tractor rake, examples of models of various categories can be given.

RCS 12

Rake of the Italian manufacturer tonutti RCS 12. This model of tractor rake belongs to the trailed wheel finger rake with a simplified design and a long service life. You can change the width of the resulting rolls and turn them over in one section. The rake is very environmentally friendly and has high speed and good performance. The power of the tractor-towing vehicle must be between 80 and 100 hp.

GVV-6.0

Rakes of Russian-made tedders-rakes are used for raking up the swath grass, which has had time to sag, turning and turning it over. They are easy to maneuver and operate economically on any field contours.

FPM Agromehanika

With the help of the Polish belt tedder rake, you can not only collect and shake the cut grass, but also turn the green mass. The conveyor-type device is very simple and reliable, it is coupled with low-power tractors, works with forward and reverse (backward) movement of the tractor. You can set the required working height.

GVR-630

Rakes gvr are produced in Belarus, belong to the rotary type of tedders (1 rotor), a hydraulic method of tine tilt regulation is used. It can also process wet raw materials, its use helps to increase the speed of drying hay. Reducers of increased reliability are used, placed in containers with oil, which ensures uninterrupted operation of the rotor. We need tractors with a capacity of 25 to 50 hp.

GVD 1-F-6.0

The trailed-type rake for tedding the main engine (production - Russia) rakes meadow grasses, freshly cut or which have already fallen through, it is possible to double the rolls. It has a fairly large weight and high performance.

Swadro

From the trailed rake rakes of the Finnish manufacturer kroone, the Svardo 800, 810 and 900 series with a raw material capture width of 3.5-15 m stand out. The working gearbox is completely closed, greased, does not require maintenance. The fingers are doubled and arranged in a basket. The suspension is equipped with two rotors.

How to choose a tractor rake

In any store of agricultural machinery there is a large selection of tractor rakes of all types, so you need to approach the purchase, correctly assessing your needs and capabilities. The main indicators are equipment productivity, raking speed, and specific energy consumption. The parameters of the rake and the technical capabilities of the tractors or mini tractors should be agreed. The larger the cultivated area, the more powerful the rake should be and the wider the coverage.

The well-known name of the manufacturer serves as the guarantee of the durability and reliability of such attachments.

DIY tractor rake

Due to the rather high price and not very complex design, many people prefer to make them on their own, often such models even surpass industrial ones in performance.

In order to make a rake for a tractor or mini-tractor with your own hands, you need:

- welding machine;

- saw-grinder;

- adjustable wrenches;

- drill for metal;

- iron rods with a diameter of 1 cm;

- tubes with a diameter of 5 cm;

- metal profile for the frame;

- cardan shaft and chain;

- Sheet steel;

- rear axle of a passenger car for a rotor;

- rims.

10 tubes of high-strength steel are welded onto the car rim in the form of a "sun"; it is advisable to drill holes in them for better grip. For mounting the rake wheels, bearings are used, put on the hubs. A hitch for attaching to a tractor or walk-behind tractor is made according to drawings using steel springs.

Swathing is one of the main operations in hay making, so a tractor tedder rake is used to facilitate and increase productivity. There are several types and designs of this useful equipment for farmers. The simplicity of the design allows you to assemble such a rake yourself, taking into account your own needs.