Content:

- Features and classification of wood splitters

- Characteristics of the cone splitter models

- Features of a hydraulic homemade wood splitter

- The nuances of the rack and pinion version of the wood splitter

- How to make and assemble a do-it-yourself rack and pinion wood splitter

- How to make a hydraulic wood splitter with your own hands

- How to make a screw-type wood splitter

- What is the difference between a factory model and a homemade one?

Modern technologies make it possible to abandon the manual chopping of firewood, in particular, you can use wood splitters. They differ in the type of drives, so their prices are different. However, it is quite possible to assemble a wood splitter with your own hands, this will not only save money, but also acquire a unit made taking into account the physical characteristics of a person who will work with the tool.

Features and classification of wood splitters

Wood splitters can be:

- hydraulic;

- electrical;

- manual (homemade).

The first type of wood splitter is based on a hydraulic press. The wood is destroyed due to the enormous force of the mechanism, which delivers a sharp and sharpened wedge, thereby cutting the wooden block into pieces. The mechanism that pushes the bars uses an oil pump, which makes these wood splitters "gluttonous". Their disadvantage is the cost of control units and pumps, as well as high prices for hydraulic cylinders.

Electric-type units work on a similar principle: the mechanism feeds wood blocks onto a sharpened wedge, however, by design, they are simpler than hydraulic ones, so an electric wood splitter can be built with your own hands in "handicraft" conditions. The downside is that this type of wood splitter must be installed on a sliding gate, without this installation it is impossible to work. The whole process of chopping firewood consists in "drilling", because the steel cone has a cut thread with a large pitch, which is screwed into the log with great force, thereby breaking it.

The third type is homemade. Any of the above types of wood splitter can be taken as the basis for the future unit, be it hydraulics or an engine, on any type of fuel. The plus is that the unit can be built from improvised means, since any high-quality mechanisms and good metal will do. It is even possible to make a wood splitter from a jack with your own hands. The downside may be that you need to make and assemble the parts yourself, and this takes time, skills and tools, but still it will be a cheap homemade log splitter.

In addition, there are several other types of wood splitters, which differ in their location in space:

- horizontal;

- vertical.

They have a different arrangement of executive elements.

Characteristics of the cone splitter models

The cleaver can be used in only two types of wood splitters - mechanical, if the cleaver will be screwed into the log manually, or electric, but in this case you will have to regulate the movement of the cleaver and its speed.

In electric versions of wood splitters, the engine must be selected according to the number of revolutions and power, since it will be inappropriate to spend especially on powerful motors, which are simply not needed in these cases.

Features of a hydraulic homemade wood splitter

This type of wood splitter is one of the most popular, since the units have a much greater power of the executing element. The devices are used on the basis of 220 V or 380 V engines that run on gasoline fuel. The effort that develops in this case for the destruction of wood should be in the region of 4 to 6 tons. Scale models with great effort are suitable for working with large birch, oak, aspen logs.

The nuances of the rack and pinion version of the wood splitter

The cleaver in the rack and pinion device is fixed on the rack, which, in turn, with a gear drive, moves. A wooden block is fixed between the stop device and the cleaver. The felling of a log occurs with the help of not only a cleaver, but also gears, then a rack with a cleaver is involved, which moves under pressure to the bar.

This type of wood splitter runs on an electric motor, so its operation cannot be called complicated. However, when working with it, it is necessary to take into account the length of the blade, the type of cleaver used, the power of the pushing force.

The gear unit is the main element in these wood splitters. The principle of operation of the mechanism is that the log lies in a special chute, after which the counter pulley rotates, and it pushes the wood directly to the cutting site. This design is very popular, but such mechanisms are quite expensive.

Benefits:

- reliability in work;

- ease of use;

- durability;

- the ability to use different drives - 220 V and 380 V;

- the ability to work with any type of wood - birch, oak, etc.

- low energy consumption.

How to make and assemble a do-it-yourself rack and pinion wood splitter

The first thing worth noting in this case is the low cost of creating a mechanism. It will not be possible to indicate any dimensions, since each person needs their own apparatus in terms of dimensions. But here is an instruction to the general principles of creating a mechanism:

- The correct drawing and scheme of work is the beginning and basis of all work. When creating, the first thing you need to calculate is not only the type of wood (birch, oak, pine and much more), with which the wood splitter will interact, but also the place where it will be mounted. Also, determine the performance, since the power and type of drive will depend on this.

- The type of frame of the wood splitter - in particular, this applies to the material. If a stationary option is needed, then a massive metal profile should be used, if a lightweight and portable one - lighter options for a corrugated board.

- Log feed speed is an important parameter as it is necessary to calculate the position of the knife. High speed will lead to the appearance of chips that can injure the one who works at the wood splitter, and if everything goes slowly, then you can simply fall asleep while doing this business.

How to make a hydraulic wood splitter with your own hands

Making a hydraulic wood splitter with your own hands is a very difficult task, because it has a complex operating mechanism. Before proceeding with manufacturing, the following components must be purchased:

- oil tank;

- pump equipment;

- special cylinder and other hydraulic system;

- flow control unit for the supplied liquid.

After purchasing the listed components, you need to make a frame, it is needed to be able to move the future device to a place convenient for work. The hydraulic base is attached to it, which includes everything that is indicated in the list of components. The final detail will be a sharp tip; a wedge is ideal for cutting logs.

How to make a screw-type wood splitter

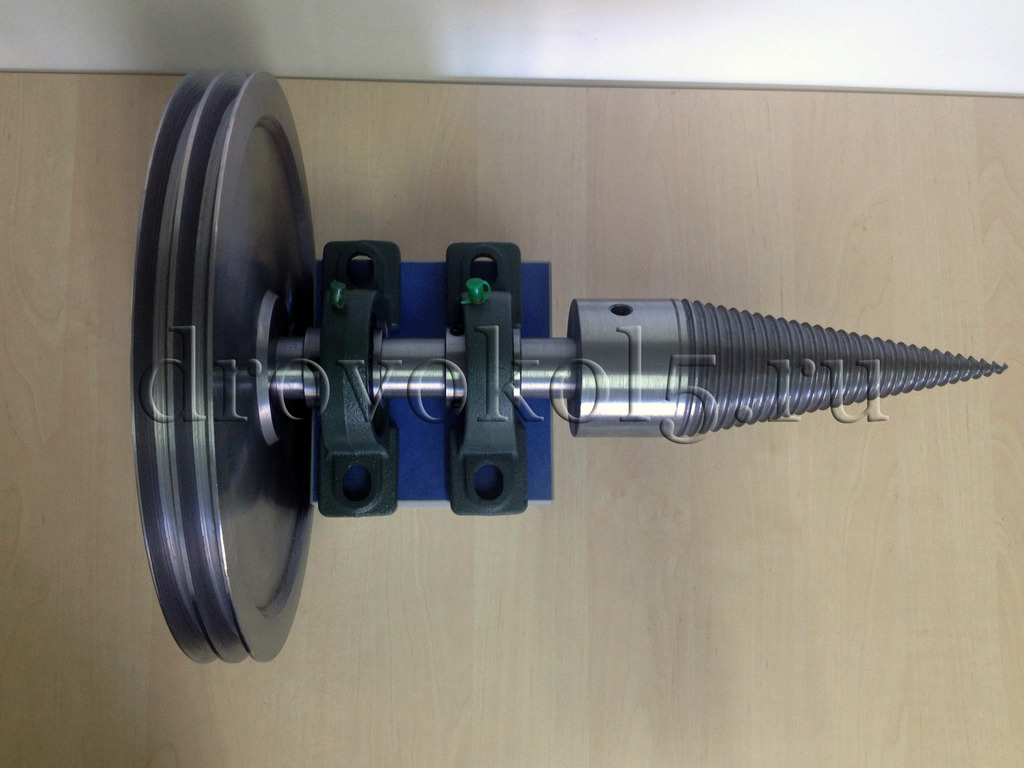

To begin with, it is advisable to purchase a screw cone, a motor, a very strong frame, a shaft and a reduction gear.

After all the necessary parts have been purchased, you can start assembling the equipment. It is necessary to take the frame and mount the motor together with the gearbox to it. Then fasten the cone to the shaft. The resulting mechanism is installed to the reduction gear using a motor.

When assembling this wood splitter, the following requirements must be observed:

- install the nozzle directly to the motor;

- use a cleaver rotation speed not lower than 250 rpm.

The principle of operation of a homemade mechanical wood splitter is as follows - a metal cone, which rotates due to the engine, chops the logs. The cone must be selected for certain conditions, if you need to cut large logs, then a large cone is needed, for medium and small bars the mechanism can be smaller.

In a screw wood splitter, it is allowed to use three types of motors - asynchronous, collector, with electronic control. In this case, a mechanical log splitter is obtained.

What is the difference between a factory model and a homemade one?

It's no secret that there is a home-made wood splitter and a purchased one, their task is the same - to chop wood, but there is a difference - this is the price. The store has a price for a certain type of wood splitter with specific characteristics. It is possible to assemble the same one only by buying cheaper components. For example, a powerful version of a wood splitter in 2018 costs about 90 thousand rubles, but if you look for its components and assemble such a model, it will cost 70, or even 60 thousand rubles, depending on where to buy individual components ...

One of the advantages, in addition to the lower price, for self-made options is that it is possible to choose components - engine, transmission type, etc. - in accordance with the individual characteristics of a person. You can build a wood splitter so that it will be convenient to work behind it, but you just have to spend time and effort on assembling it.

Homemade wood splitters are suitable for private households where work will take place in a comfortable environment. However, at enterprises it is more expedient to use ready-made units so as not to waste time and effort on assembling manual models.