Content:

With the constant rise in energy prices, many private home owners are thinking about alternative ways to heat their own premises. Often, the choice falls on solid fuel boilers that use firewood as fuel. But, as a rule, firewood is sold as logs, sometimes sawn along the length of the boiler furnace - this is cheaper for the buyer. In this case, you will have to prick them yourself. This activity adds physical health, but takes away strength.

There are several ways to mechanize this process. One of the most common tools for this is a hydraulic log splitter. This article discusses its features and tells whether it can be assembled at home.

Device

Although there are a lot of wood splitter varieties, almost all of them are assembled according to the same scheme. There are four main nodes in such schemes. The rest are auxiliary, increasing the usability of the tool.

- The base unit is the wood splitter frame. Much depends on its quality. It is a fastening element for all the main nodes of the wood splitter and the reliability of the tool depends on its strength. The weight of the bed also plays an important role, since the stability of the wood splitter and the ability to chop large wood depends on it.

- The engine is the heart of the wood splitter. It can be gasoline or electric. The advantage of a tool with a gasoline engine is its autonomy, the electric one depends on the proximity of the electrical network and its parameters.

- The hydraulic unit is an additional link between the engine torque and the forward movement of the cleaver. The performance of such wood splitters depends on the maximum pressure developed by the hydraulics.

- The cleaver is usually made of high quality metal. The manufacturer guarantees that this structural element will have a resource not less than the wood splitter itself.

What are hydraulic wood splitters?

There are many parameters by which you can organize this tool. The first is the plane of the location of the log.

By this parameter, wood splitters can be combined into the following types:

- vertical;

- horizontal;

- adjustable.

By performance, it can be divided into:

- household;

- industrial.

What to look for when choosing a wood splitter

It is necessary to pay attention to the manufacturers of equipment for splitting firewood and consider their advantages and disadvantages.

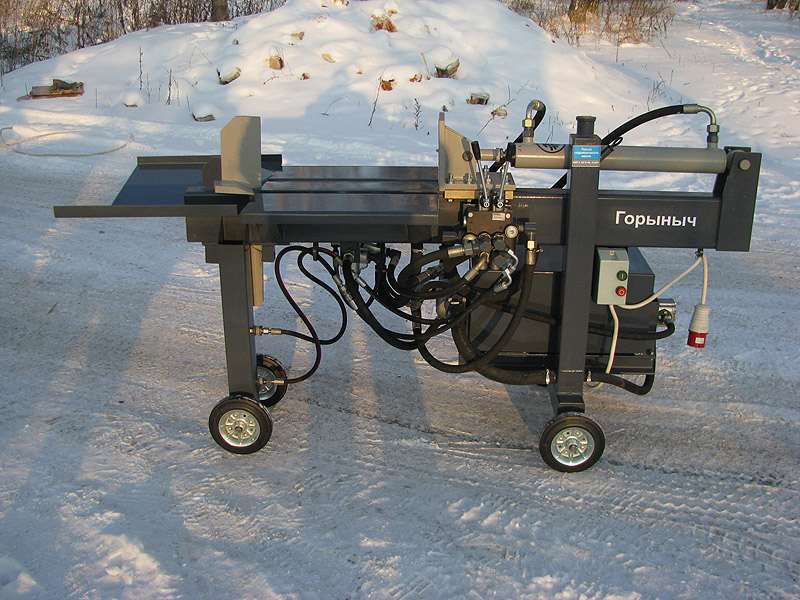

Wood splitter "Gorynych"

This is a professional instrument of domestic production. Production shops are located in the Kaluga region. The technical characteristics and diagram of the Gorynych wood splitter can tell you how best to use it.

If we consider a specific model "Gorynych 6T", then we can evaluate its performance. The wood splitter can work continuously, and the hydraulic equipment for the wood splitter is designed for 10 thousand cubic meters of firewood. The billet length is 50 centimeters, which is suitable for most boilers.Three-phase electric motor 380 Volt. The force that it transfers to the cleaver is 6 tons.

Industrial wood splitter Japa

This model also represents a cohort of professional equipment made in Finland. The wood splitter "Yapa 60" is different from its Russian counterpart.

In the model range of these wood splitters there are tools that are powered by electricity (4 kW 380 Volt engine), there are options with an installed gasoline engine, and it is also possible to connect the Japa industrial wood splitter to the tractor's hydraulic system. It also allows you to split longer pieces. Their maximum length can be 67 centimeters.

Wood splitter made in Finland "Palaks"

This equipment can be produced in two categories:

- With attachments for sawing firewood.

- No sawing, just a wood splitter.

The powering of the Finnish wood splitter "Palax" is similar to its Finnish counterpart "Yapa". Also has three options. Those customers who do not have a three-phase power supply in their wood-burning warehouses can order equipment with an electric motor. And although it will cost the buyer more, its autonomy can be a big plus for such equipment.

Some models allow you to split logs up to 110 centimeters long and up to half a meter thick. The hydraulic cylinder for such a wood splitter should be much more powerful and more effort should be applied.

Self-assembly of a hydraulic log splitter for personal use

The main problem of using the wood splitting equipment described above at home is its price. In addition, the equipment is rather bulky and heavy. At home, processing of such a large amount of firewood is rarely required. Therefore, quite often, craftsmen prefer to develop a homemade version of wood splitting equipment.

On the Internet, it is quite easy to find a drawing of a hydraulic wood splitter developed by craftsmen. Moreover, not only read about the features of a particular design, but also see with your own eyes how such equipment works. Although such a model in its appearance may be inferior to industrial models of wood splitter, nevertheless, in terms of reliability and efficiency, it is not inferior to them, and some samples even surpass.

It is also important enough that craftsmen do not keep their designs secret. They are ready to share all the intricacies of designs.

Main questions:

- What kind of food will a home wood splitter have? Perhaps the easiest option is electric. When choosing in favor of it, it is necessary to decide whether a single-phase network will be enough or a three-phase one is needed. The solution to this issue depends on the power input to a particular household.

- What equipment performance is required to provide the farm with firewood? How often and to what extent firewood will be split during a certain time.

- What size firewood is needed. The length of the bed, its weight and engine power depend on this. Also, an appropriate hydraulic system is selected for this power.

After the answers to the questions have been received, you can choose the model of the hydraulic wood splitter that would satisfy all the specified requirements. Then you should start the selection of materials. It is important to choose only high-quality materials. Those work that cannot be done at home must be ordered in industrial production, paying special attention to the materials from which the wood splitter will be made. After that, you should start assembling the equipment itself.

Build quality determines the efficiency of the equipment. It is also important to pay attention to the aesthetic side of the hydraulic wood splitter. Because it is necessary that the wood splitter not only works reliably and for a long time, but also looks beautiful.