Content:

There is always a lot of work in the garden, but one of the hardest and most tedious is digging up the earth. In small areas, this work is done with a shovel, but it takes away strength. However, there is a special tool that will allow you to do this job with much less effort. The story about what a miracle shovel drawings and dimensions for its manufacture will be in this article.

What can a miracle shovel

This tool provides additional opportunities for the farmer.

The miracle shovel provides the summer resident with the following advantages:

- When digging earth with its help, much less effort is required compared to using a conventional tool.

- The quality of soil loosening during such processing increases. If lumps form, they will break into pieces during operation.

- Some designs have a back stop. In the process of digging the soil, you can step on it to help yourself immerse the tool in dense and heavy ground.

- If there are roots of weeds in the ground, then the lazy shovel will get them out as a whole, and not cut them into pieces.

- This tool is useful for digging up potatoes.

- The digging speed is much higher than in the usual way.

In appearance, the excavator shovel resembles a pitchfork with additional details.

It includes the following parts:

- The shaft for which a person holds the instrument.

- Metal forks with tines about the same length as conventional forks, but about twice as wide. They usually have 6 to 8 teeth.

- A metal stop going backwards is attached to the forks. When the miracle shovel is immersed in the ground, you can put pressure on it with your weight, so that the tool goes into dense ground more easily. It also serves as a stop when turning the shovel out of the ground.

- In the forward direction, a horizontal grate is attached, set so that the forks go up and pass through it. With this movement, clods of earth find themselves between the forks and the grate, as a result, crumble into small pieces.

Here is a description of the typical structure of the Krotchel shovel. In practice, several different options for its design are used.

How to work with a shovel

In order to dig up the ground, you need to stand with your back in the direction in which you have to move.

In order to use this tool, you need to do the following:

- Stick the shovel into the ground. If it is difficult to do this due to the density of the soil, you need to step on a metal stop.

- After the shovel has entered the ground, the shaft must be tilted back without lifting it off the ground. In this case, the ground, which is hooked by the pitchfork, will pass through the grate and crumble.

- Then the shovel, without lifting it up, is shifted back and again immersed in the ground.

This process is repeated until the entire section has been completed.

Various tool options

There are fixtures that, although arranged in a similar way, have important design differences. Further on they are described in more detail.

Soil cultivator without front stop

There is no front stop in this type of design. The clod breaker is made without a front bar. This slightly reduces the weight of the mole ripper shovel.However, since there is no need to lift the shovel off the ground during operation, this does not provide a significant advantage.

Digger

This option differs from the classic one in that it does not have a front grill. The tool handle is also made in a different way.

The digger consists of the following parts:

- It uses a pen made in the shape of the letter "T". Therefore, in the process of work, the shovel is not held as usual. Hand hold the instrument by the horizontal bars. This helps to increase the force of pressure on the soil when working. In addition, this handle is usually made of metal. It can be extended up or down. After finding a comfortable position, the handle is bolted.

- The pitchfork is attached to the handle at two ends, and not at the central part, as in the classic version.

- A stop attached to the back of the tool is more powerful than usual.

The disadvantage of this design is that soil crushing is not provided.

Easycop

This option can be considered the simplest design. For her, a rectangular metal frame had to be invented, to which a pitchfork was attached, looking down. A rectangular stop is attached horizontally. The front grill is missing.

Archimedes' shovel

It bears little resemblance to the classic version. The difference, in particular, is that here, for digging, not a pitchfork, but a bayonet shovel is used. However, the inventor applied a similar principle here: the rule of leverage. This is an invention of Vladimir Kolybelin from the city of Kovrov, Vladimir region.

The Archimedes' shovel is arranged in this way:

- She has two shafts: long and short.

- The tool blade is attached to a short shaft.

- All parts are connected in one piece by the bracket. With its help, a short shaft with a shovel in the middle is connected to a long handle and can rotate.

When working, the tool is stuck into the ground, the long handle is slightly shifted forward. Then they step on the short part, and, taking into account the law of the lever and the length of the arm, the shovel will lift the ground.

How to make yourself

You can make such a shovel yourself, but for this you need to be able to work with metal, for example, to perform welding. This section will tell you how to make a miracle shovel with your own hands, about the drawings and dimensions for making it.

Materials

The main part of the structure is made of metal. To do this, you can take a profiled pipe or corner. The thickness should be approximately 30 mm. In the latter case, the steel used is important, it should not be thinner than 3 mm.

The handle can be made of wood or metal pipe.

Dimensions

The width of the working part is usually from 60 to 80 cm. If you make more, then this practically does not add productivity. The recommended length of the pins is from 22 to 30 cm.

The length of the handle is made according to the height. It will be convenient if it reaches the shoulder.

Blueprints

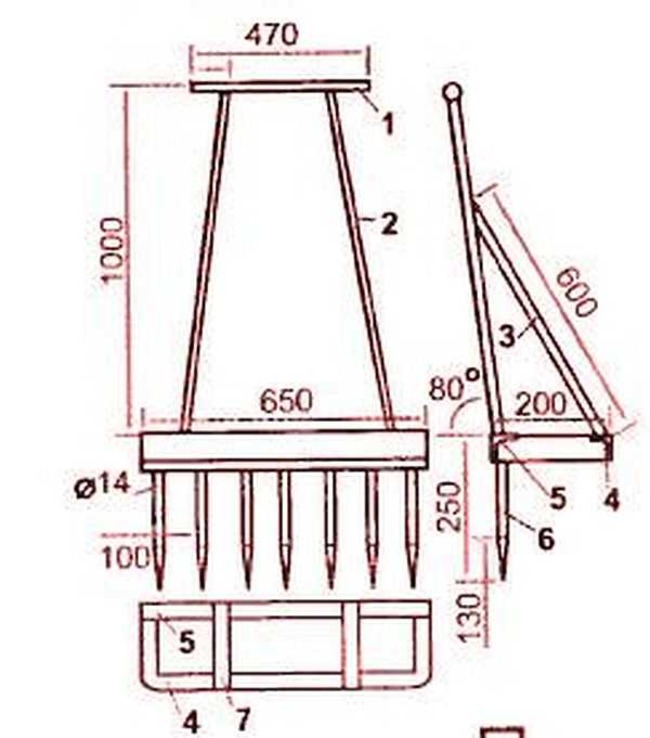

The figure below shows one of the options for how to make a shovel.

In accordance with this diagram, it is possible to make the instrument yourself.

The miracle shovel greatly facilitates the work of digging up the site. You can do it yourself. If possible, it makes sense to purchase a high-quality commercial model.