Why do horses need horseshoes, because before, even before humans tamed and domesticated them, animals did not need them? The explanation is simple: in the wild, these hoof protection devices are not needed. The animals traveled long distances on soft soil or grass, and chose their own path. After they became domesticated, became completely dependent on a person, everything changed. If the horse served as a cab, he had to transport goods or people along cobblestones or stone roads. The riders were always well armed and dressed in heavy chain mail. All this put a lot of stress on the horse's hooves. Therefore, in order to protect the soles of the animal's feet, a person invented a kind of shoes for them - horseshoes.

Shoeing horses began to be practiced from the third to fourth centuries AD among those peoples who mastered the extraction of metal. Before that, horse "shoes" were made from leather or reeds, but these shoes were short-lived. The first such horseshoes were used in Asia. They were replaced by hoof shoes resembling iron sandals. Only in the third century a new shape of curved horseshoes was invented, which almost do not differ from modern ones. In Russia, horse shoeing began to be practiced after the decree of Peter the Great in 1715 "On the training of blacksmithing in each province of Russian people." Over time, the presence of a forged horse spoke of the status of its owner.

What are horseshoes for?

Now everyone knows why horses are shoeed. Horse hooves are strong enough to move on virgin soil, avoiding sharp stones, crevices. Instinctively, wild horse herds knew how to choose their own paths. Currently, horses are kept in the stables for a long time, do not have freedom of movement. For this reason, the stratum corneum of the hooves softens and wears out quickly. This leads to cracks and other injuries, through which dirt and all kinds of germs get in, inflammation begins. At first, the animal limps from pain, and then does not want to move at all.

To avoid this, horse hooves need to be forged in a timely manner. Why do horses need horseshoes? They help not to slip on wet ground, grass or during ice. By protecting and correcting injured or deformed hooves, horseshoeing makes it easier for horses to move. In equestrian sports, savvy horses are easier to overcome obstacles and look sleeker and more graceful during dressage. To do this, use different types of horseshoes, depending on the purpose. For the front hooves, rounded fittings are made, and for the hind hooves, they are slightly elongated. This corresponds to the physiological structure of the equine limbs.

Horseshoe design

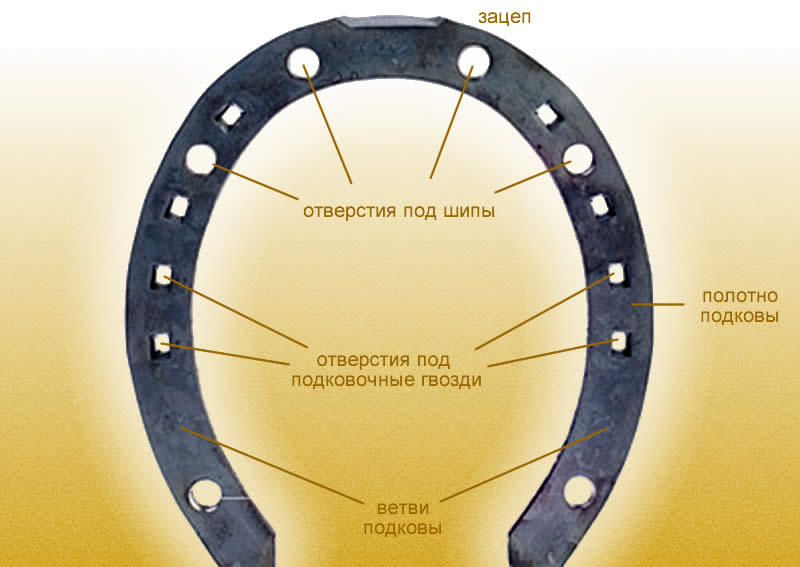

A simple horseshoe is a metal curved plate with branches (part of the horseshoe from toe to heel). There are two of them: internal and external. The upper, or inner, surface of the plate is adjacent to the hoof, and the lower, outer surface is in contact with the ground when walking. At the front of the web is a hook or lapel, a small ledge. The horseshoe has a path for nails, holes for spikes that help grip the horseshoe to the ground, an inner and outer side edge. By the way, the thorns must be attached during the period of ice or during the races on the frozen ground.In short, the surface of the horseshoe is divided into three main parts: toe, side and back.

The plane of the horseshoe, adjacent to the stratum corneum (or horn), is conventionally divided into external and internal. The outer surface is large and should be flat and perfectly fitted to support the entire hoof. On the lower, also horizontal, but not solid surface, there is a nail track. Hats of nails, drowning in it after nailing, are not erased. There is no track in the toe and heel area. Nail the horseshoe carefully so as not to damage the tissue under the cornea. Use 6, 8 and 12 nails, matching the size. There are 13 sizes of horseshoes in total. On sale they are presented in pairs for the hind and forelimbs.

Varieties of products

They are divided into three large groups: standard, sports and orthopedic. Within each group there are types of horseshoes that are intended to be used as intended.

Standard plain horseshoes are used for workhorses. Their mass depends on the size: it ranges from 200 to 700 grams. Manufactured with removable studs. Winter horseshoes have a pointed elongated shape, and summer ones, on the contrary, are rounded and low. They are made both in factories and by professional blacksmiths.

Sports horseshoes are used for forging horses taking part in various equestrian competitions. They can be aluminum, steel, titanium, depending on the type of competition. For example, for horse racing, horseshoes weighing no more than 120 grams are used, and for all-round athletes, products are used heavier, up to 200 grams, and more massive, with thickening and bumpers on the sole.

Orthopedic structures can be made of steel, aluminum or plastic, taking into account individual injuries or the condition of the hoof cornea. Products are used for the rehabilitation of a sick or injured animal.

Forging tools

A real professional blacksmith or blacksmith knows how to nail a horseshoe correctly. He is well aware of all the tools used in this difficult process. A standard set is usually used, consisting of a crochet (hook for hoof care), pliers for removing old horseshoes, a cleaver or a knife for removing an old layer of the sole, a forging hammer, a rasp, a file for hooves, nails (s), pliers for removing nails and of course anvils. They can only be used once, they cannot be reused. Few blacksmiths can handle this task these days. You need to have some knowledge about how to properly shoe a horse, how to trim the horse's hooves before doing this, how to clean the horseshoe from rust, and many other secrets in handling these animals.

Forging process

How often do you need to shoe horses? It all depends on the physical activity of the animal and the rate of regrowth of the cornea on the hoof. For ordinary workhorses, forging is done every 30 days, for sports horses - more often.

Domestic horses, which rarely ride on an asphalt road, do not need to attach horseshoes at all.The forging procedure is not quick, because the animal first needs to get used to the master, only then you can gradually start to work. Sometimes the process itself takes several days. How is it carried out? First you need to remove the old horseshoes, then clean the sole well, removing the dirt. After that, measurements are taken, after trying on you can nail a horseshoe. But this diagram is the big picture. If we consider the whole process, then it can be broken down into 10 stages:

- Stage 1. It is not difficult to crochet the edges of the hoof from sawdust and various debris so that it is convenient to take off the old "shoes". It is important to do this carefully.

- Stage 2. Then with pliers, with a sharp movement, tear off the horseshoe with nails.

- Stage 3. It is necessary to thoroughly clean the hoof again, then cut off the regrown cornea from the hoof with a hoof knife.

- Stage 4. File the surface and edges with a hoof file so that it is smooth and flat. Why? Because it depends on how exactly the horseshoe will fit.

- Stage 5. In the same sequence, clean and process the other three limbs.

- Stage 6. Measurements are taken and the horseshoes are fitted.

- Stage 7. Re-try the product and pin it to the hoof. This is the most difficult and crucial step. A small inaccuracy can lead to leg injury. If all the conditions of forging are met, the animal will not feel discomfort, because there are no nerve endings in the horn. Hammer in the nails in the required sequence (1st - into the first hook hole, 2nd - opposite, and so on to the end) and strictly at right angles to the horseshoe.

- Stage 8. Bend the ends of the nails with a hammer, pin them to the lower edge of the hoof and fit the toe tightly.

- Stage 9. Remove the ends of the nails by cutting. To do this, the horse's legs need to be raised one by one on special iron supports, which are placed in front of it and under its belly.

- Stage 10. Final. Rasp the edges of the horseshoe and hoof again. If necessary, fasten the spikes. Since there are no holes for them on the new horseshoes, you can drill with your own hands so that they correspond to the diameter of the thorn.

This completes the shoeing procedure. Thus, with a certain set of tools, skill and love for animals, the forge can successfully shoe any horse.

In the modern world, you rarely meet a person who is keen on horses. Questions such as "Does a horse hurt when shod?" and "What are horseshoes made of?" you can hardly get a correct answer from ordinary people.